AFCAB certificate for MBT couplers

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

![[Translate to Anglais:] LEVIAT a CHR company](/fileadmin/_processed_/0/5/csm_logo-leviat-white_bf42d08d02.png)

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry.

Leviat’s engineered products and innovative construction solutions are used in a variety of market segments from residential to infrastructure, enabling users to build better, stronger, safer and faster.

3 000

employees

+60

sites worldwide

4

production on 4 continents

+30

sales in +30 countries

Blankenberge will soon have a brand-new sports complex and Leviat was allowed to contribute to

that.

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

We imagine, model and make engineered products and innovative construction solutions for a dynamic industry. We support our partners in the long term to build better, safer, stronger and faster and help turn awe-inspiring architectural visions into reality.

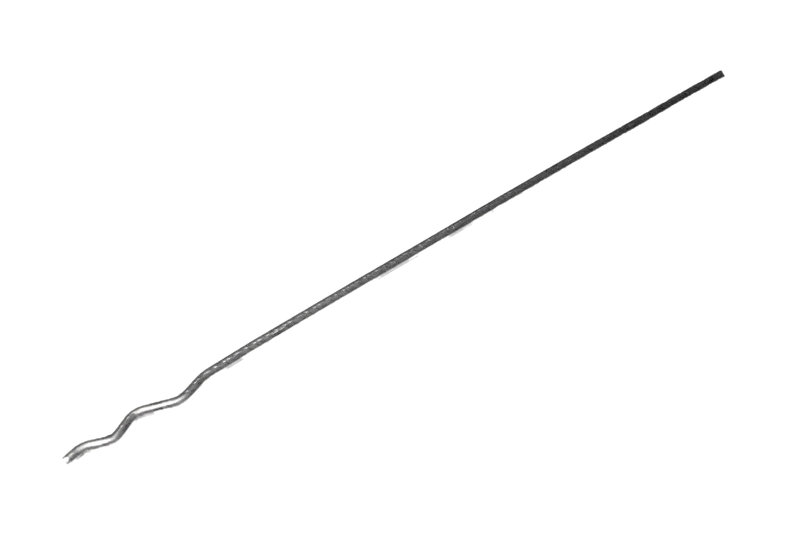

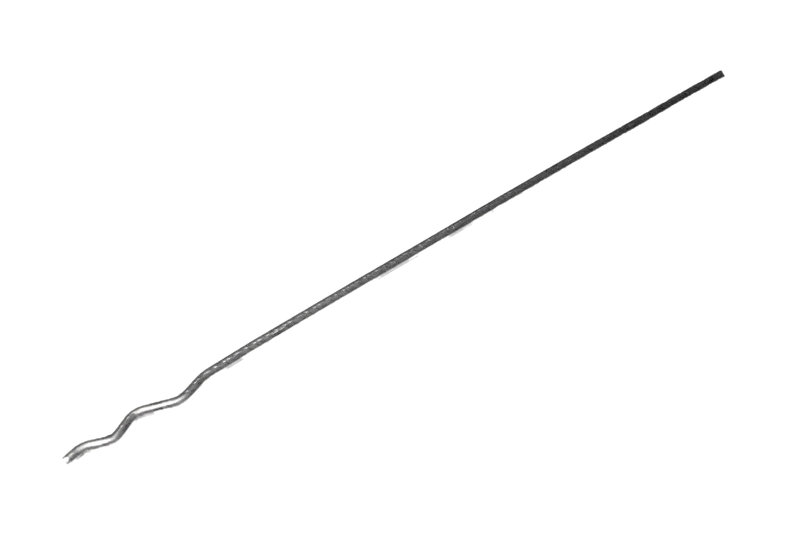

Murgrip is a stainless steel masonry hook to be punched into a reinforced concrete structure. The double ripple at the end of the hook is designed for optimum anchoring without using a dowel.

Scope of application: Anchoring facing masonry in the case of a double wall with a structure in reinforced concrete.

It is highly recommended to use the drift punch to avoid bending the Murgrip when fastening it.

• The length is determined by the width of the gap in the hollow wall. Ensure the masonry hooks are anchored deeply enough at both ends.

• Eurocode recommends using stainless steel masonry hooks (MX3 exposure class).

•Quantity: as specified by the stability engineer (Calculation imposed by Eurocode 6 - NBN EN 1996-1-1 with a minimum 5 p/m² as per the Belgian National Annex)

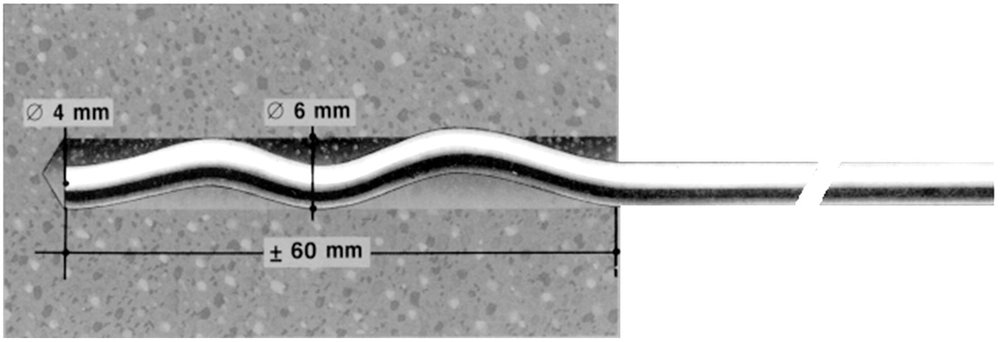

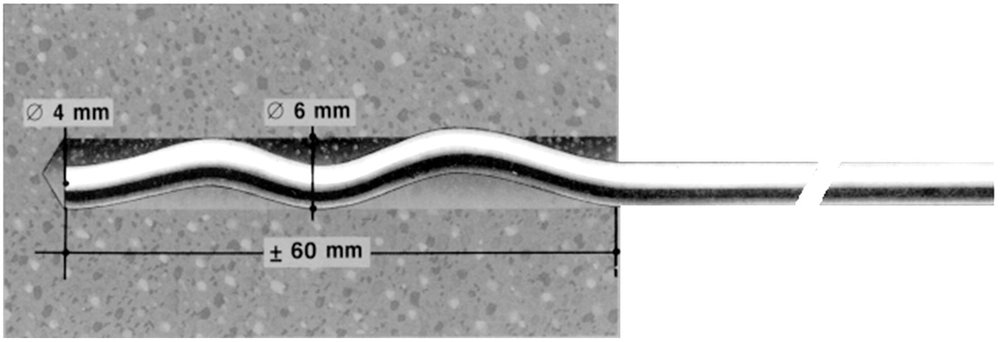

- Drilling a hole in reinforced concrete, 6 mm diameter and 60 mm minimum depth.

- Place the rippled side of the hook in the hole.

- Punch the hook to the bottom of the hole, using a hammer and the appropriate driving punch.

- If applicable, add an insulating fixed clip directly against the insulator.

- Fold the tip of the hook using the hook pliers.

- Install the anchoring hooks tilted outward to avoid water from passing towards the loadbearing wall, or add a drop breaking washer on the hook before the installation.

Murgrip is a stainless steel masonry hook to be punched into a reinforced concrete structure. The double ripple at the end of the hook is designed for optimum anchoring without using a dowel.

Scope of application: Anchoring facing masonry in the case of a double wall with a structure in reinforced concrete.

It is highly recommended to use the drift punch to avoid bending the Murgrip when fastening it.

• The length is determined by the width of the gap in the hollow wall. Ensure the masonry hooks are anchored deeply enough at both ends.

• Eurocode recommends using stainless steel masonry hooks (MX3 exposure class).

•Quantity: as specified by the stability engineer (Calculation imposed by Eurocode 6 - NBN EN 1996-1-1 with a minimum 5 p/m² as per the Belgian National Annex)

- Drilling a hole in reinforced concrete, 6 mm diameter and 60 mm minimum depth.

- Place the rippled side of the hook in the hole.

- Punch the hook to the bottom of the hole, using a hammer and the appropriate driving punch.

- If applicable, add an insulating fixed clip directly against the insulator.

- Fold the tip of the hook using the hook pliers.

- Install the anchoring hooks tilted outward to avoid water from passing towards the loadbearing wall, or add a drop breaking washer on the hook before the installation.