Korbo 02.01.01

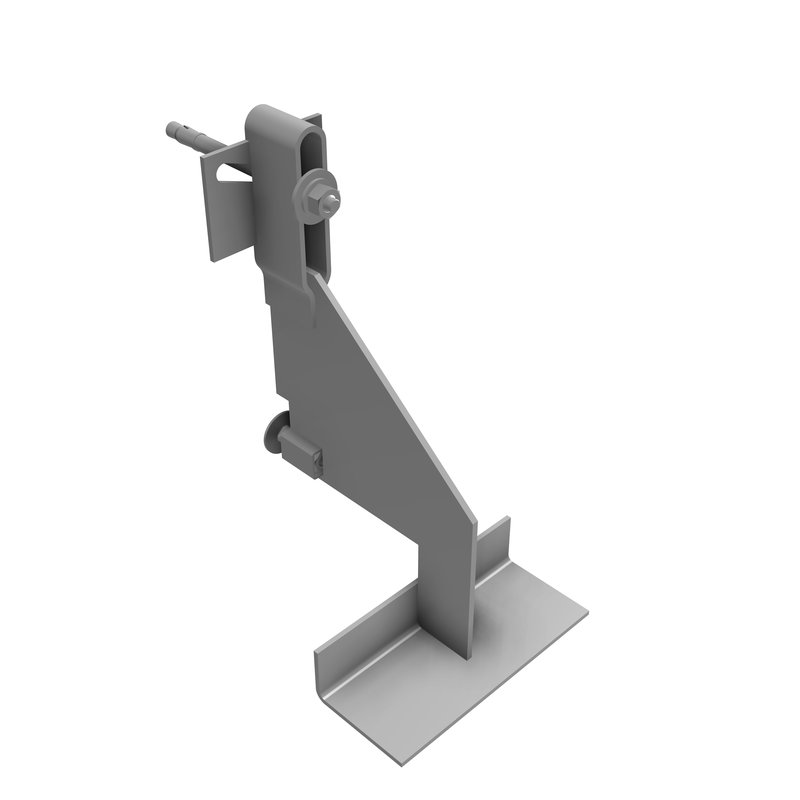

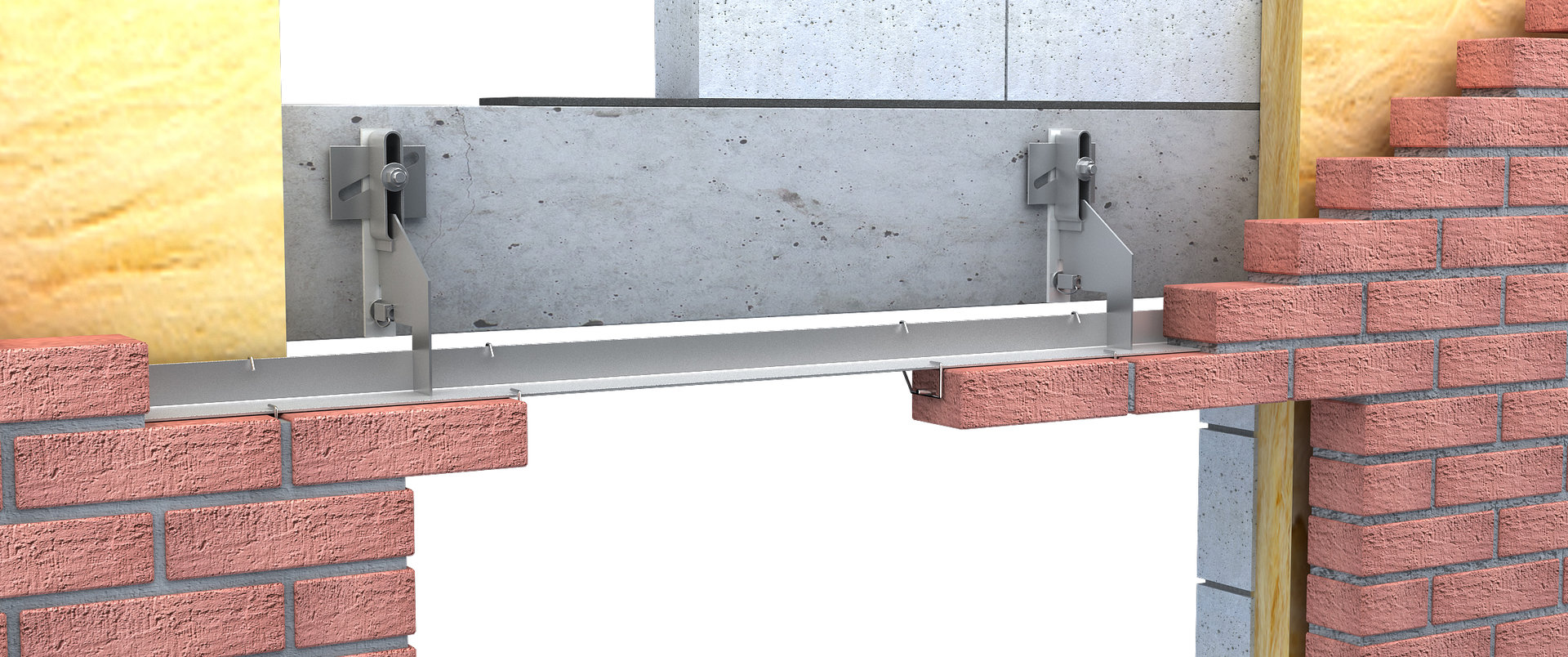

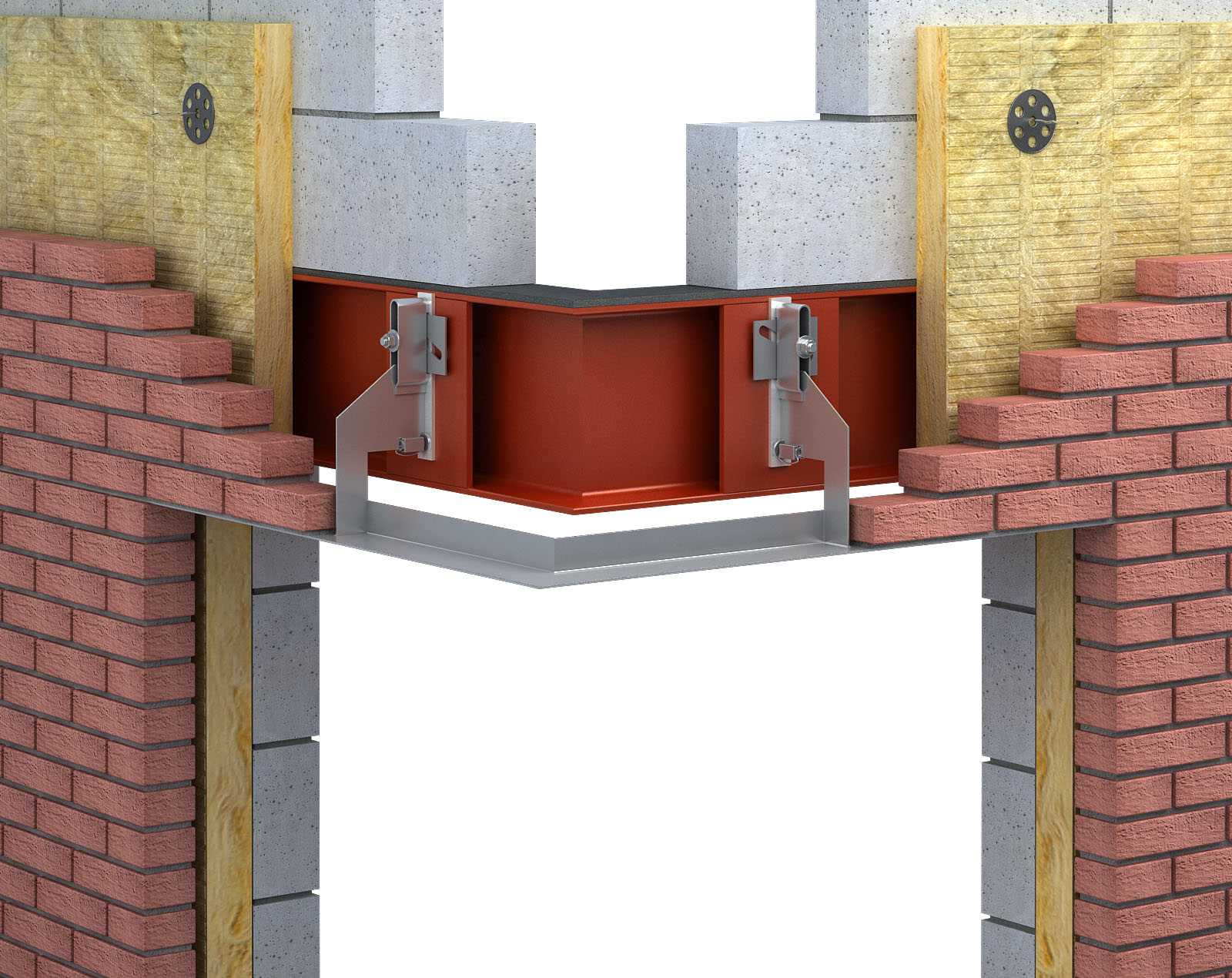

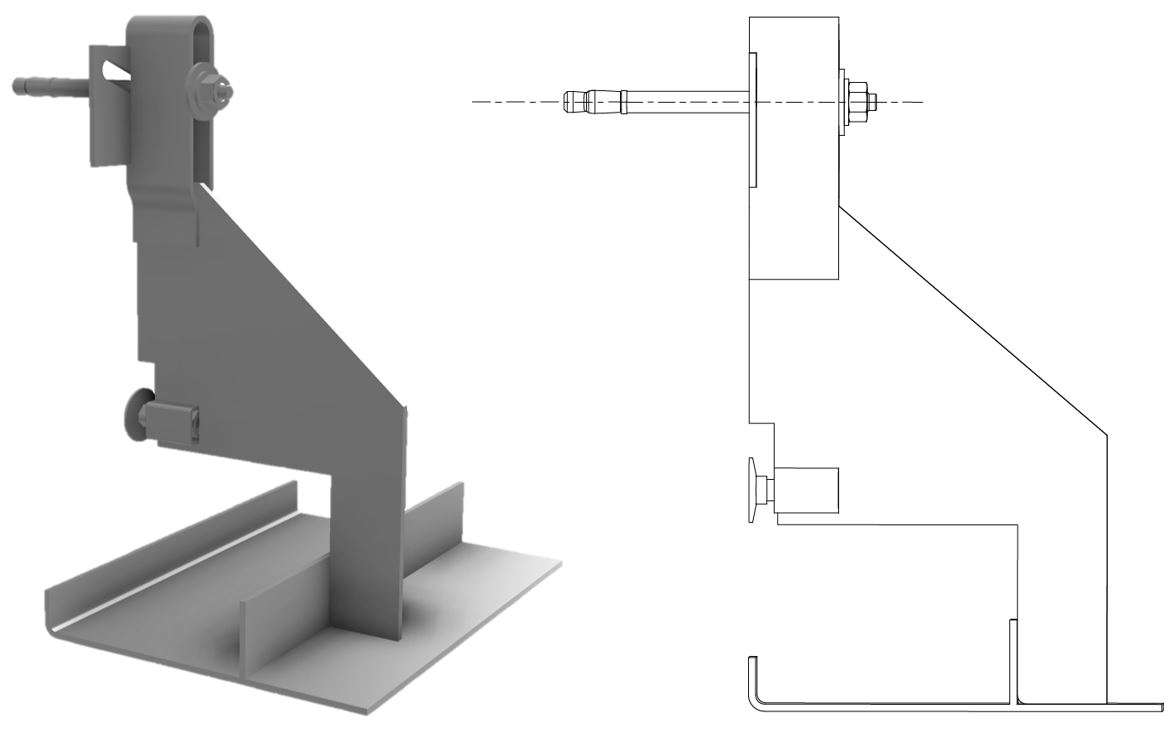

Add to my wish listThe Korbo profile is designed to withstand façade masonry beside openings or overhangs, and to create a possibility of expansion wherever necessary. Korbo angle pieces with or without welded consoles can be visible or made invisible. Consoles allow for precise adjustment and mounting.

- Simple and easy installation

- Continuous height and depth adjustment

- Calculated per project and custom-made: applicable in all situations

- Technical support from our sales team and our engineering office

- Calculation note and installation plan included

- Thermal values χ available for PEB calculation

- The Korbo masonry supports meet the Eurocodes requirements and have been tested in authorised independent laboratories

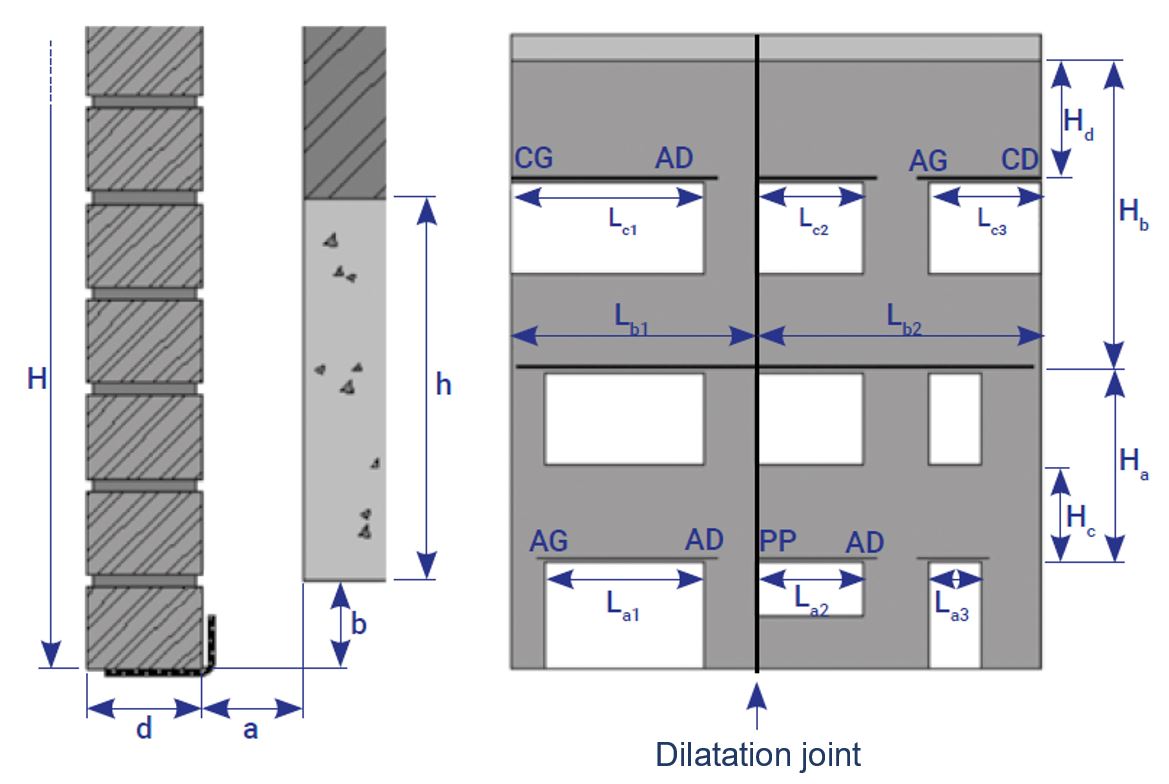

- Beware the height of the load-bearing structure during design to allow for anchoring the consoles.

- In the case of a horizontal expansion joint, a 5 mm free space must always be included under the Korbo masonry support. An elastic material can be used to finish the expansion joint.

- The watertightness flap is placed above the console in the first horizontal joint available. A second membrane is placed below the console between the joinery and the masonry, or is cut locally. In the documentation of the Korbo Dry membrane, you will find clear installation details.

Characteristics of the materials

Standard version in hot galvanised steel

Also available in stainless steel 304L or 316L

Coating powdered in the RAL colour of your choice on request

Metallisation also possible (only for lintels without consoles)

In addition to a higher resistance to corrosion, stainless steel also has a thermal conductivity coefficient which much lower than that of galvanised steel. Hence choosing stainless steel Korbo is much more useful for passive houses and low energy constructions.

Support structure and fasteners

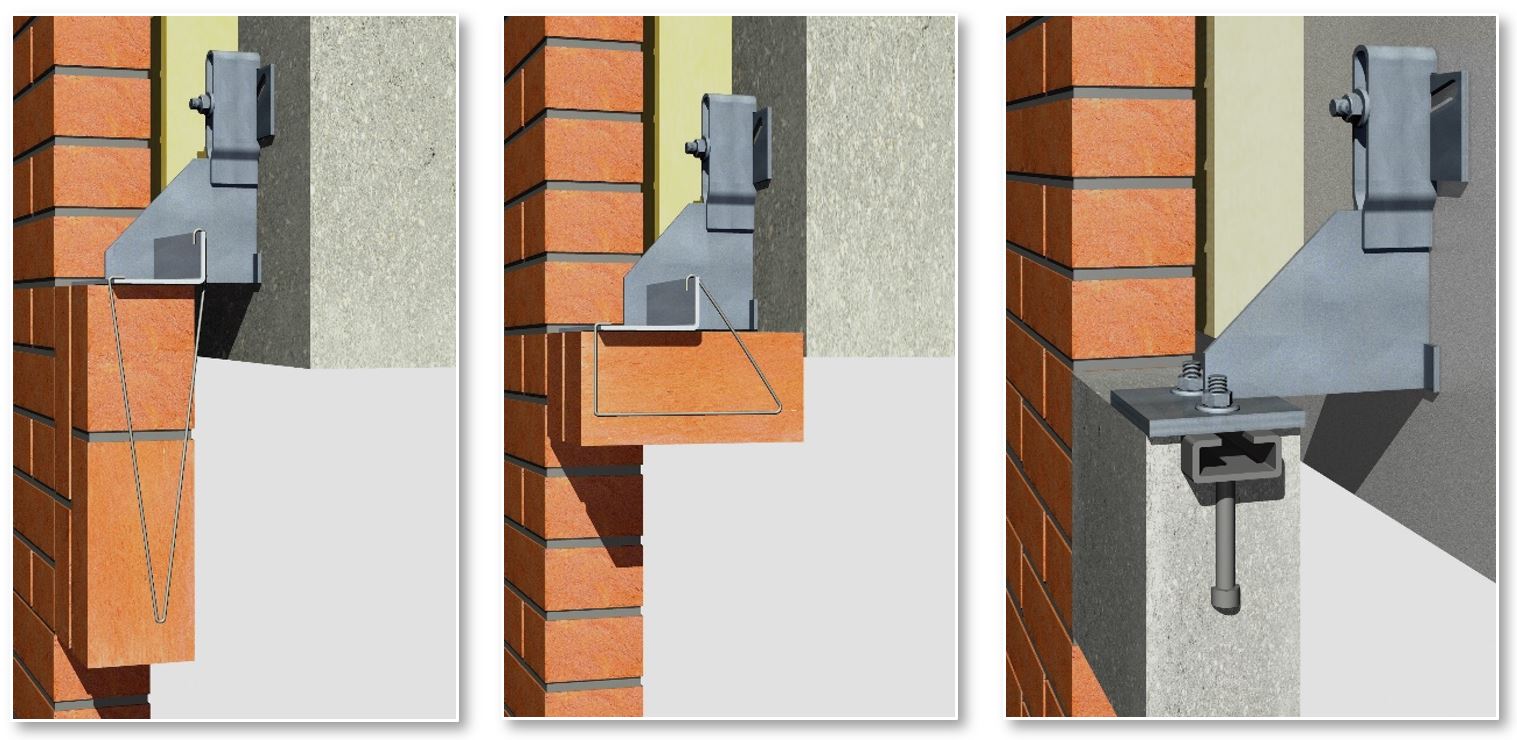

In a reinforced concrete beam, Korbo consoles can be fastened with extendable FSA bolts or cast anchor rails and hammer head bolts.

On solid concrete blocks, hollow concrete blocks filled with concrete, and sand-lime blocks, the consoles must always be anchored chemically.

For fastening onto a metallic bin, a made-to-measure weld-on flat is supplied, against which the console can be fastened with a bolt and a nut.

All the fastening means necessary are determined by our engineers and supplied with the Korbo.

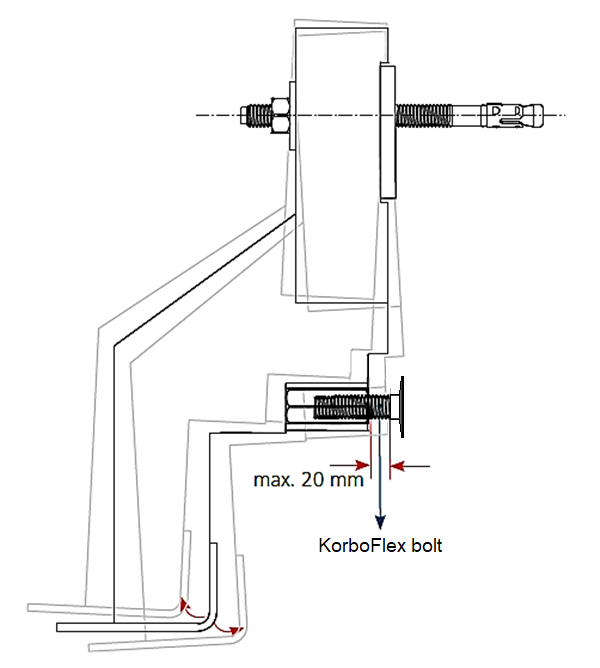

1. The KorboFlex adjustment bolt in the lower part of the Korbo allows continuous depth adjustment, independently of quality (flatness) of the carrying structure, hence allowing a perfectly horizontal corner to be obtained.

2. The KorboFlex adjustment bolt has a 20 mm adjustment range.

For optimum positioning, you can also use our range of thickness adjustment plates, as well as different types of thickness plates.

By default, most Korbo consoles are currently fitted with KorboFlex adjustment bolts.

The console height can be adjusted by 25 mm in both directions, by sliding the adjustment plate in the upper part of the console.

All Korbo masonry brackets are calculated per project and are made-to-measure. This allows using the system in all situations.

A few examples of frequent special versions:

1. Invisible execution

By using special stainless steel stirrups, horizontal and vertical facing bricks can be suspended under the angle to achieve invisible execution. In addition to a broad range of standard stirrups, supports can also be manufactured specifically for the project.

Concrete elements can also be suspended under the Korbo consoles if fitted with anchorage rails embedded in concrete.

2. Korbo with gap cover

With ever increasing gaps, we can offer solutions to cover gaps in the lower section. We apply particular care to the design of our corners to ensure that the lower face offers the best possible finish.

3. Anti-rodent grid

Perforated profile used at the wall base to prevent nuisance by rodents on the level of the insulator and close the gap space under the insulator. This product can be delivered separately or fastened directly on the Korbo corners. This product is made-to-measure.

4. Rounded façade

For a rounded façade, several small pieces of façade support can be used. If the masonry support remains visible, a special made-to-measure Korbo is always constructed with the same rounding as the façade.

5.Moucharabieh

Our experts find solutions to all market specificities. This is why we have developed a range of products meeting the gear demanded in Moucharabieh. Please call our technical department for more information.

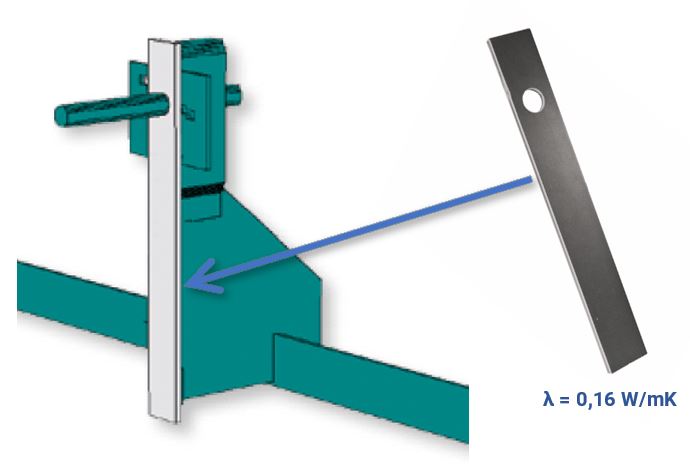

1. Thermi-K - Thermal insulation board

Installing Thermi-K boards reduces heat loss. Fit these Thermi-K boards between the console and the supporting structure. For more information about this solution, go to the Thermi-K web page.

2. Korbo-Dry Vacuum waterproofing membrane

A simple and fast solution to fit a waterproofing membrane above Korbo corners. For more information on this solution, as well as details on how to install the waterproofing on top of Korbo masonry supports, go to the Korbo-Dry web page.

1. Always specify the following in your quote request:

• Architectural drawings (floors, façades, cross-sections, details)

• Stability plans

• Please check whether all dimensions required have been indicated in the drawings, particularly the total width of the cavity and the pan.

• Indication of all horizontal and vertical expansion joints, where present

• Execution required for each detail: visible or invisible (type)

• Material required (galva/stainless steel) and finish (coating, RAL colour)

• Optionally: BIM model if available

GULDEN ROOS IN BRUGES

The "Gulden Roos", a project in Bruges nestles in an environment of alleys, squares and a central park garden. The…

Offices ACV at Roeselare

In the heart of Roeselare, the ACV is constructing a brand new office building with an accompanying underground car…

Hof van Saeys in Dendermonde

In the centre of the city of 't Ros Beiaard, where the former Abbey school stood, an oasis of peace and greenery is…