Thermal break Isotec 01.03.01

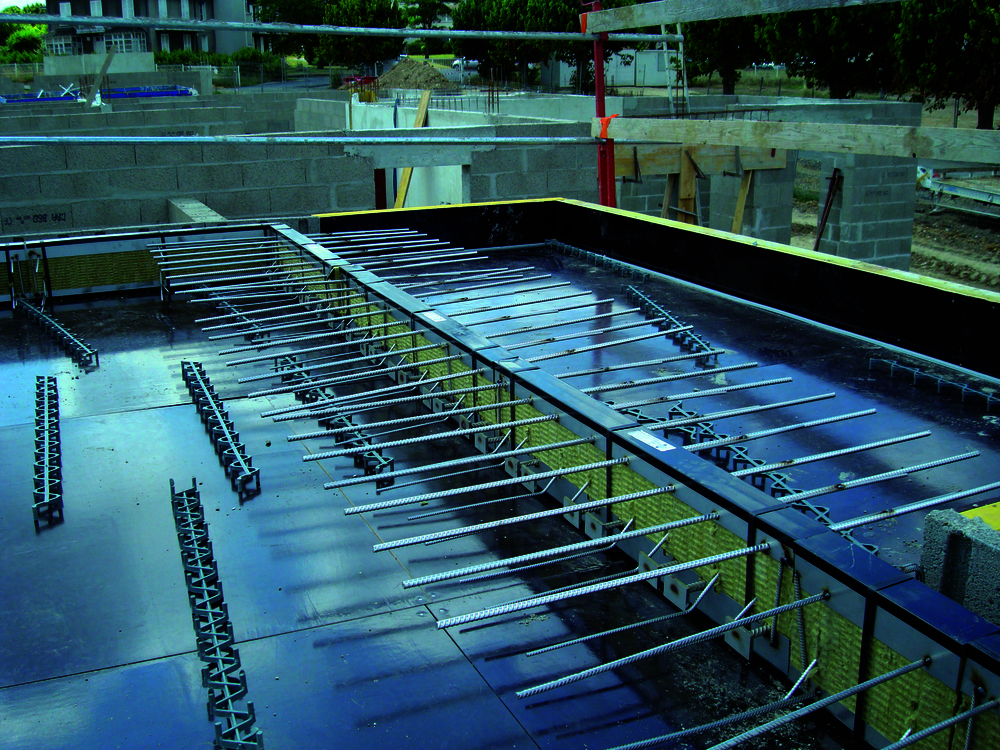

Add to my wish listThe Isotec thermal break is a reinforcement system with the main function of eliminating thermal bridges caused by structure elements overhanging reinforced concrete structures (balconies, cornices, canopies, etc.).

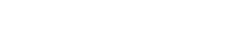

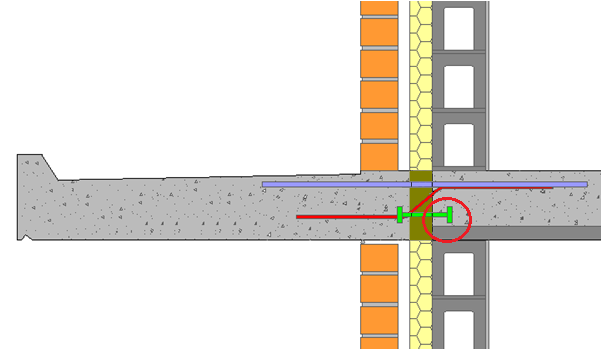

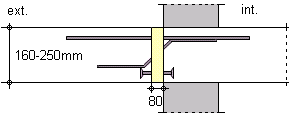

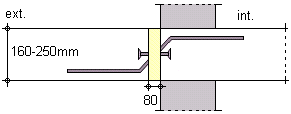

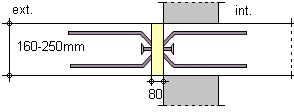

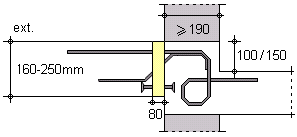

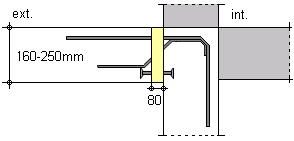

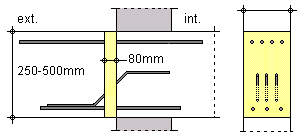

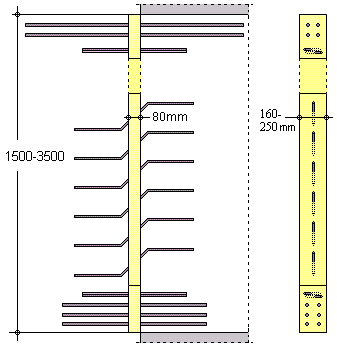

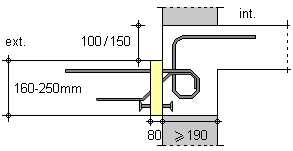

The Isotec break forms a load-bearing connecting element between concrete construction elements. The heart of the Isotec elements is made of an insulation board in PIR or mineral wool. The insulation board is crossed by stainless steel bars. This reinforcement is cast in the concrete on either side of the insulator, and therefore connects the two construction elements

The Isotec thermal break must always be planned at the beginning of a project to ensure the insulator remains continuous beside the corbels.

- Continuous stainless steel bars: 100% reliable in stainless steel over the entire length

- When the balconies are stored vertically or stacked, there is no risk of rust stains on the architectonic elements

- Using rock wool insulation ensures very high resistance to fire

- Isotec transmits the loads from overhanging elements such as balconies, cornices, acroterions, etc.

- Isotec was designed to withstand shearing and/or flexion loads

- Therefore any traditional project can be performed with an Isotec element

- Reinforced with stainless steel mounting plates ensuring high robustness during transport and fitting on the worksite

Isotec is an element which is stable and rugged due to its composition. Therefore, it is highly resistant and withstands transport and worksite handling conditions very well. Composed of mineral wool, it offers fire resistance exceeding 90 minutes. The compression studs offer additional safety in terms of anchoring in the two concrete elements.

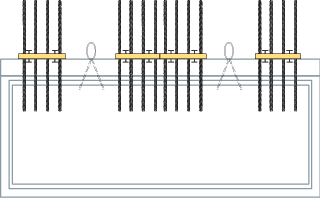

1. Check that the Isotec elements have not been damaged during transport or storage, and comply with the approved calculation note

2. Identify the elements to be placed on your balcony, based on the calculation note supplied by our design office

A technical and financial study is offered by our technical and commercial department once the following information has been received:

/Datum level map

/Cross-section at the overhang point

/In certain cases, the values calculated for the cutting force and bending moment as determined by the project's design office, while specifying whether these values are weighted or not.

Before initiating production, the calculation note issued shall be approved by the project's design office. Special made-to-measure elements may be produced in our workshops.

Once fitted in our workshops, the Isotec elements are carefully placed in secured baskets, protected by a plastic cover to prevent any damage during transport.

A thermal survey of our elements integrated into your building can be performed upon request.

3. DMV: Slab-slab or shell-shell junction with positive or negative shearing force and bending moment transfer

5. MV/SH: Slab-slab junction with different levels with positive shearing force and bending moment transfer

RTBF in Brussels

The RTBF gets a new home! The French-language broadcaster will get a new building with 7 floors above ground and another…