AFCAB certificate for MBT couplers

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

![[Translate to Anglais:] LEVIAT a CHR company](/fileadmin/_processed_/0/5/csm_logo-leviat-white_bf42d08d02.png)

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry.

Leviat’s engineered products and innovative construction solutions are used in a variety of market segments from residential to infrastructure, enabling users to build better, stronger, safer and faster.

3 000

employees

+60

sites worldwide

4

production on 4 continents

+30

sales in +30 countries

Blankenberge will soon have a brand-new sports complex and Leviat was allowed to contribute to

that.

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

We imagine, model and make engineered products and innovative construction solutions for a dynamic industry. We support our partners in the long term to build better, safer, stronger and faster and help turn awe-inspiring architectural visions into reality.

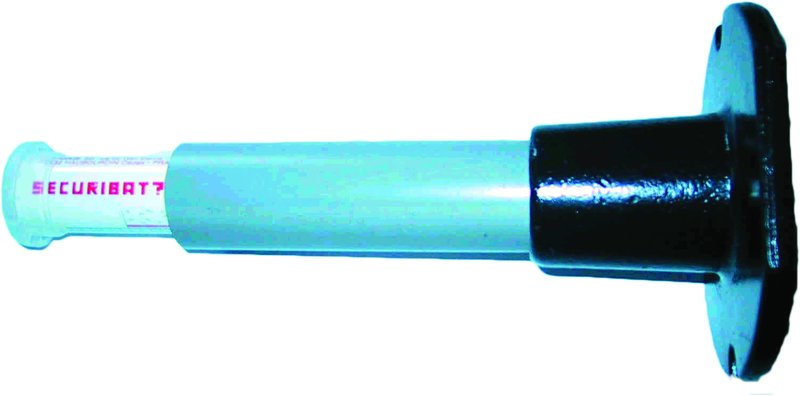

This permanent anchoring device is used to stow safety equipment. (PPE, scaffolding suspended from the façades, nacelles, etc.).

It participates effectively in the integration of safety, not only during construction or rehabilitation, but also during maintenance interventions (D.I.U.O. - File of Subsequent Works on Installations).

Compliant with the NF EN 795 - AI standard.

It is embedded in the masonry upon construction or implanted after drilling a rehabilitation in the frame with a threaded rod and nut.

The company will assess the type of tube according to use.

Principle of fitting in rehabilitation type

A/ The wall drilling must be as perpendicular to the wall as possible.

B/ The drill hole is 34 mm diameter. It is followed with a bore on the inner side with a diameter of 45 mm and a depth of approx. 70 mm.

C/ Insert the anchor on the inner side.

D/ Check that the alignment between the plate / tapped hub alignment and the PVC sheath is correct (thanks to a Securibat Systems threaded rod, with a dimension equal to the overall length of the anchor +50 mm). The fitting of the threaded rod, as well as its screwing and unscrewing, must be performed easily, without friction or locking.

E/ Fasten the plate to the wall with two dowels and screws 8 mm in diameter (anticorrosion treated).

F/ Once the anchor has been fastened, check the alignment again.

G/ Remove the threaded rod. Fit the plug at the end of the PVC sheath as per the technical instructions.

Instructions for use for the Securibat Systems masonry anchor

1/ Remove the plug as per the technical instructions.

2/ Measure the anchor depth using a rule.

3/ Order a Securibat Systems threaded rod of a length equal to the anchor depth +50 mm by Securibat Systems. Only this make guarantees product compliance.

4/ Grease the end of the threaded rod before inserting it into the anchor.

5/ Screw the threaded rod fully by hand; the length is 30 mm, i.e. 7 and a half turns.

6/ Together with its nut, this anchor is now ready to receive the Securibat Systems working and protection equipment.

7/ Do not forget to refit the plug after us.

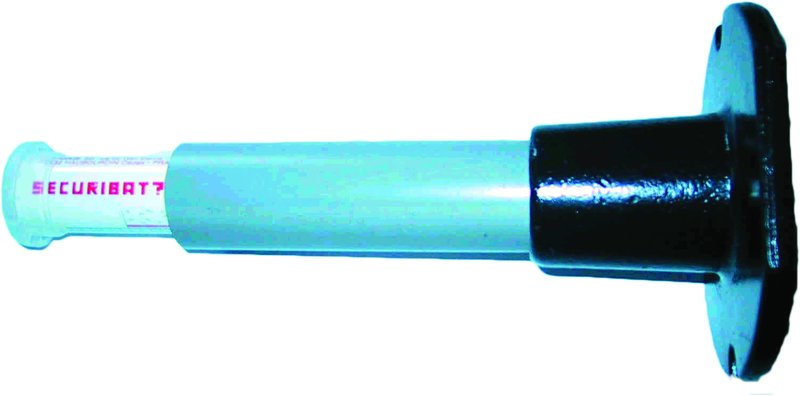

This permanent anchoring device is used to stow safety equipment. (PPE, scaffolding suspended from the façades, nacelles, etc.).

It participates effectively in the integration of safety, not only during construction or rehabilitation, but also during maintenance interventions (D.I.U.O. - File of Subsequent Works on Installations).

Compliant with the NF EN 795 - AI standard.

It is embedded in the masonry upon construction or implanted after drilling a rehabilitation in the frame with a threaded rod and nut.

The company will assess the type of tube according to use.

Principle of fitting in rehabilitation type

A/ The wall drilling must be as perpendicular to the wall as possible.

B/ The drill hole is 34 mm diameter. It is followed with a bore on the inner side with a diameter of 45 mm and a depth of approx. 70 mm.

C/ Insert the anchor on the inner side.

D/ Check that the alignment between the plate / tapped hub alignment and the PVC sheath is correct (thanks to a Securibat Systems threaded rod, with a dimension equal to the overall length of the anchor +50 mm). The fitting of the threaded rod, as well as its screwing and unscrewing, must be performed easily, without friction or locking.

E/ Fasten the plate to the wall with two dowels and screws 8 mm in diameter (anticorrosion treated).

F/ Once the anchor has been fastened, check the alignment again.

G/ Remove the threaded rod. Fit the plug at the end of the PVC sheath as per the technical instructions.

Instructions for use for the Securibat Systems masonry anchor

1/ Remove the plug as per the technical instructions.

2/ Measure the anchor depth using a rule.

3/ Order a Securibat Systems threaded rod of a length equal to the anchor depth +50 mm by Securibat Systems. Only this make guarantees product compliance.

4/ Grease the end of the threaded rod before inserting it into the anchor.

5/ Screw the threaded rod fully by hand; the length is 30 mm, i.e. 7 and a half turns.

6/ Together with its nut, this anchor is now ready to receive the Securibat Systems working and protection equipment.

7/ Do not forget to refit the plug after us.