AFCAB certificate for MBT couplers

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

![[Translate to Anglais:] LEVIAT a CHR company](/fileadmin/_processed_/0/5/csm_logo-leviat-white_bf42d08d02.png)

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry.

Leviat’s engineered products and innovative construction solutions are used in a variety of market segments from residential to infrastructure, enabling users to build better, stronger, safer and faster.

3 000

employees

+60

sites worldwide

4

production on 4 continents

+30

sales in +30 countries

Blankenberge will soon have a brand-new sports complex and Leviat was allowed to contribute to

that.

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

We imagine, model and make engineered products and innovative construction solutions for a dynamic industry. We support our partners in the long term to build better, safer, stronger and faster and help turn awe-inspiring architectural visions into reality.

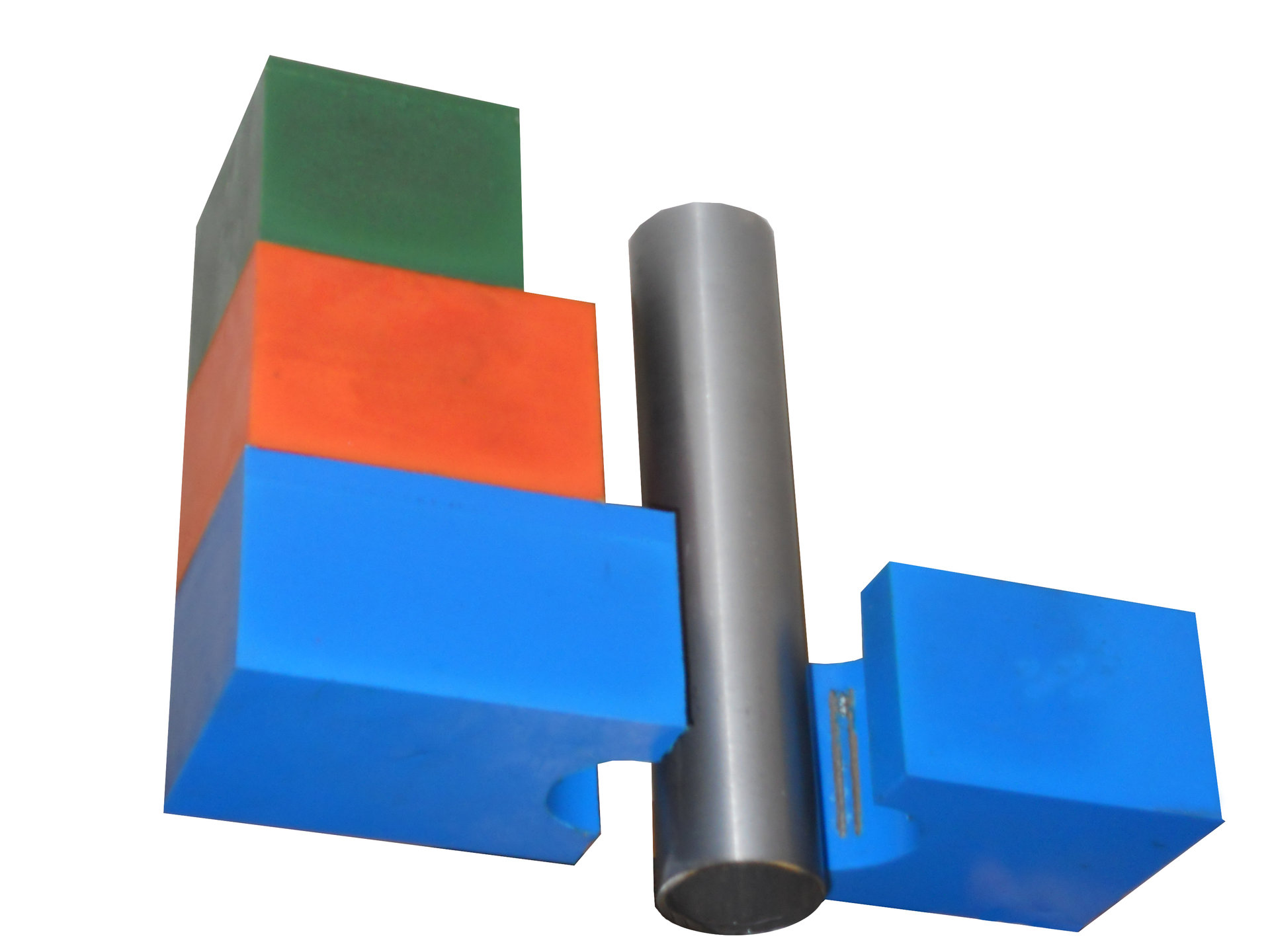

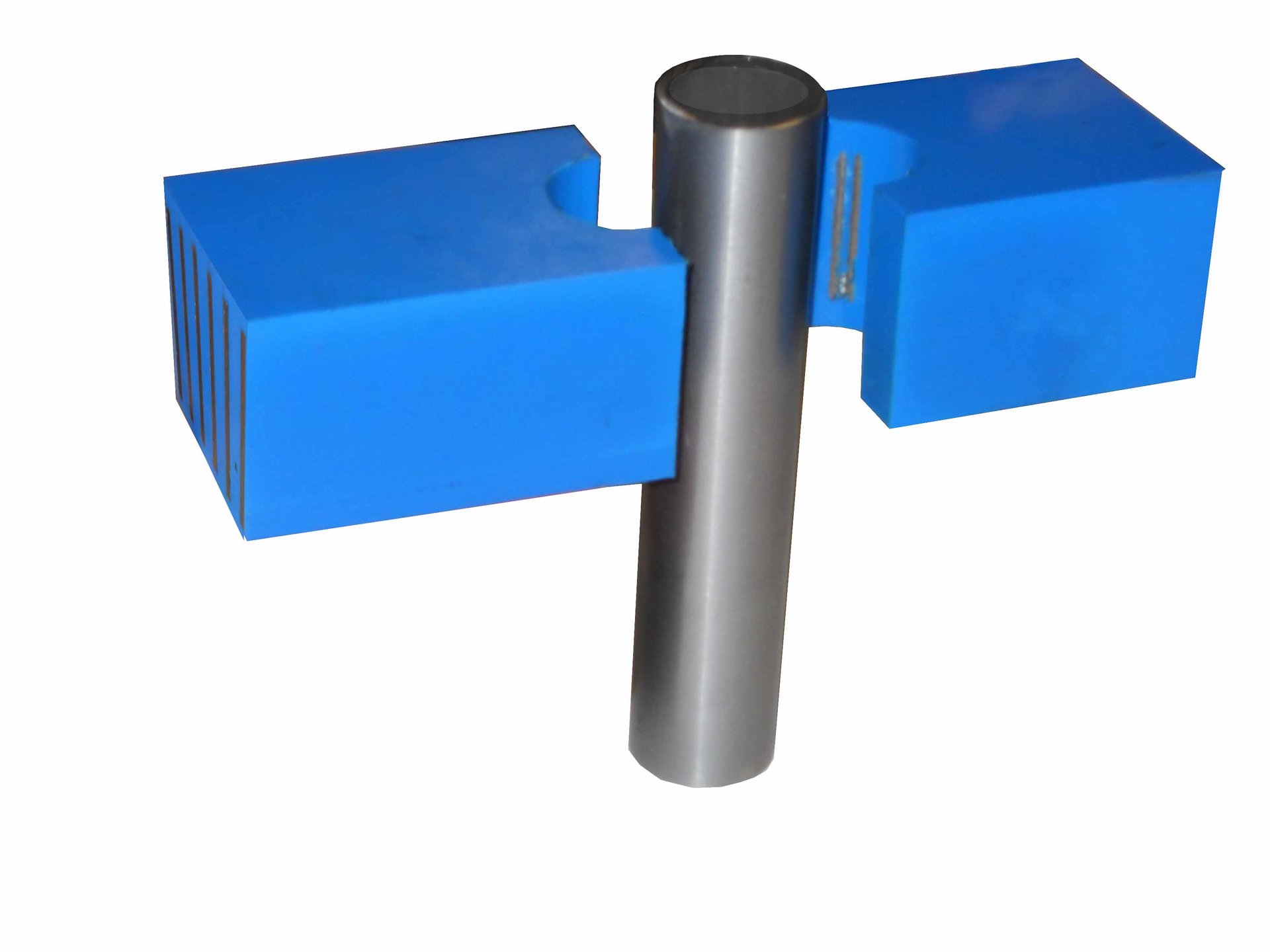

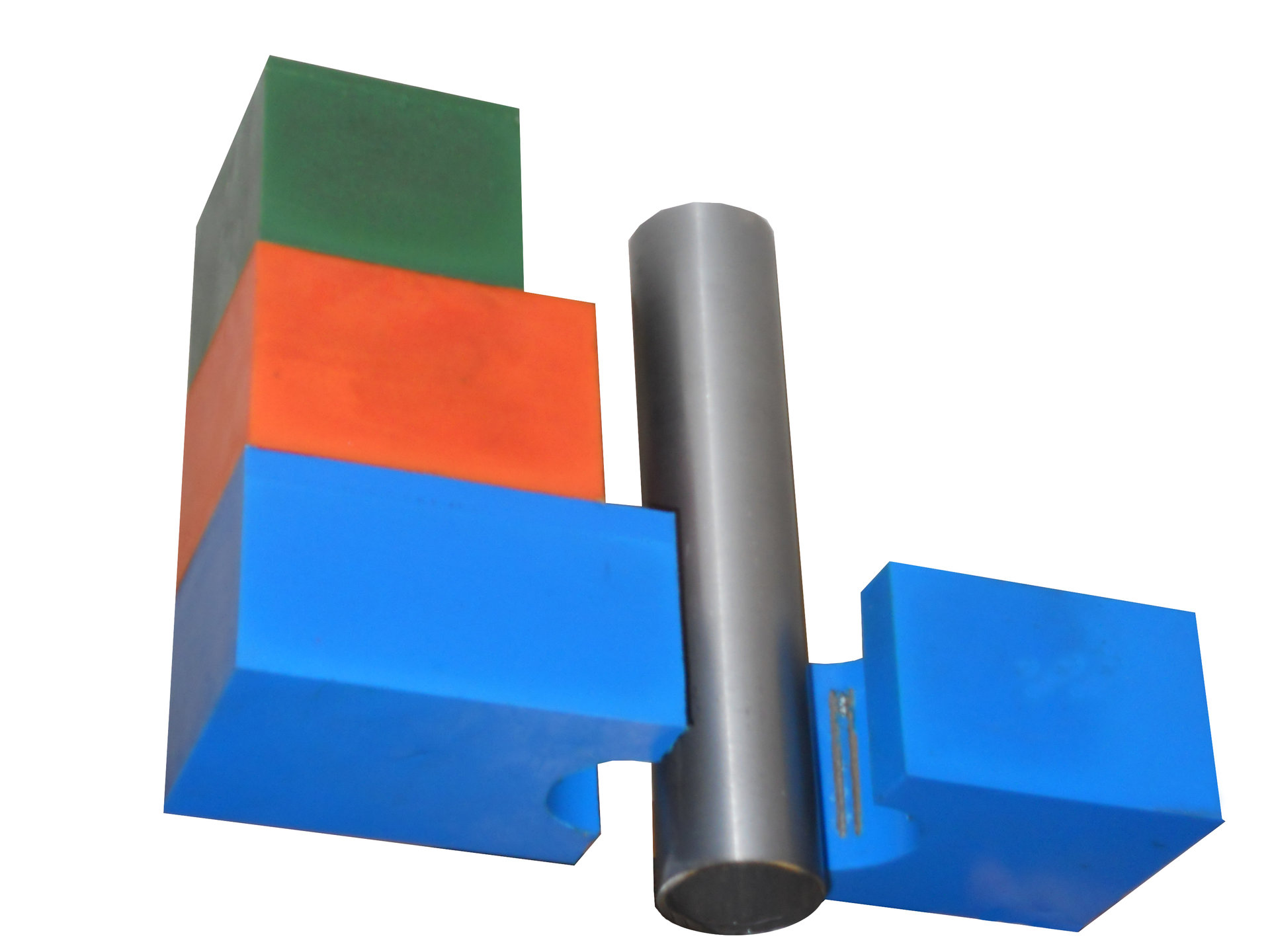

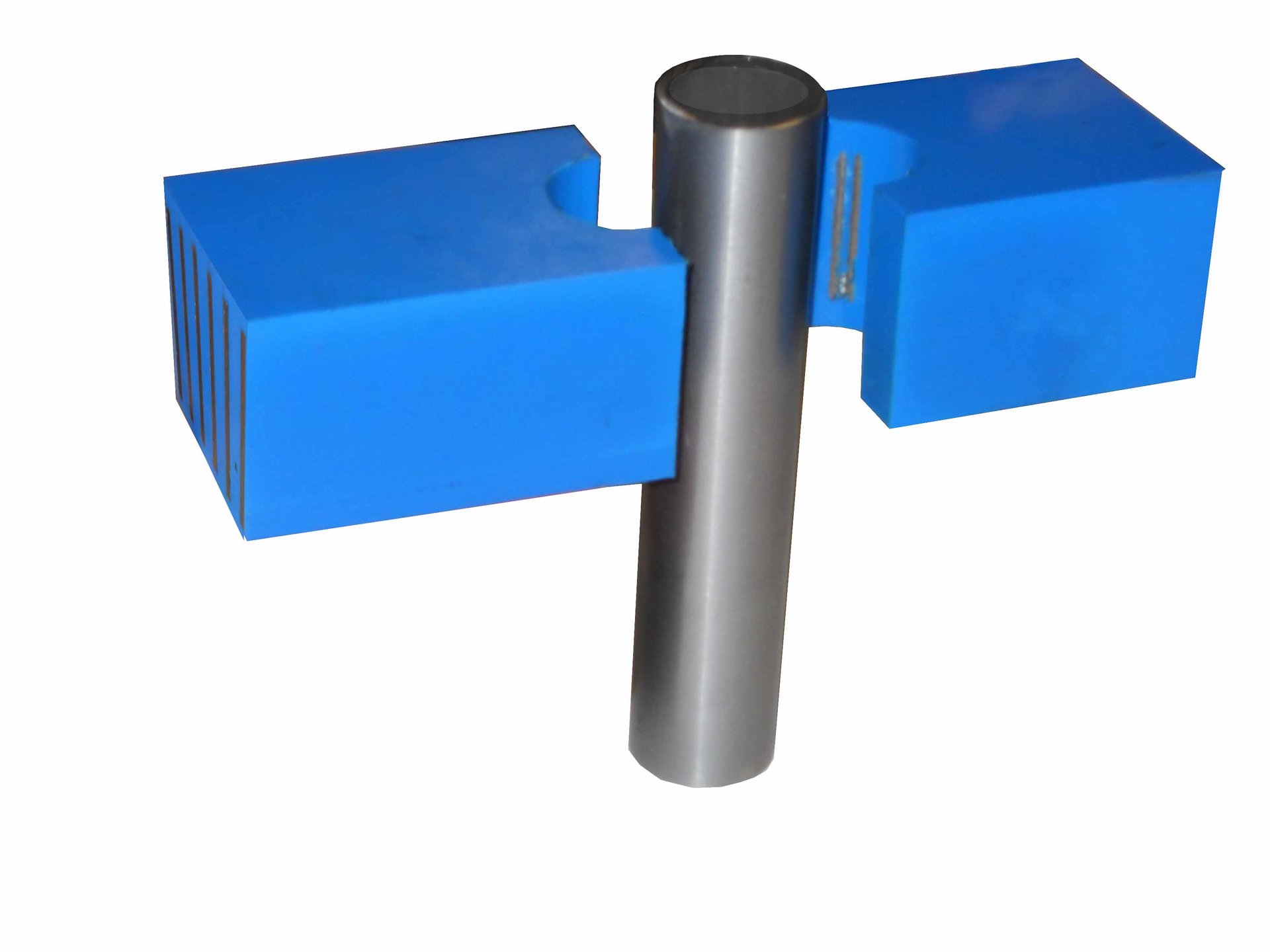

In steel or PVC, railing standbys are used to create a standby in fresh concrete on the shell head, balconies or prefabricated parts (wherever a railing protection is required) in order to implant the railing foot and hence secure the worksite.

The company will assess the type of tube according to use.

This product is a major contribution to safety, as it ensures the perfect positioning of steel tubes.

- More specifically, it prevents the steel tube from being tilted towards the gap

- No small parts or adjustment system

- Easy and fast to use

- Very high number of reuses

- No wooden spacers

- The use of a complete system with the compensation blocks avoids fitting spacers in the upper part of the shells

- The magnetised fastening studs for the steel tubes prevent them from being cast in the BAP

- Composed of two parts: one for shimming and another for adjustment according to shell thickness

In steel or PVC, railing standbys are used to create a standby in fresh concrete on the shell head, balconies or prefabricated parts (wherever a railing protection is required) in order to implant the railing foot and hence secure the worksite.

The company will assess the type of tube according to use.

This product is a major contribution to safety, as it ensures the perfect positioning of steel tubes.

- More specifically, it prevents the steel tube from being tilted towards the gap

- No small parts or adjustment system

- Easy and fast to use

- Very high number of reuses

- No wooden spacers

- The use of a complete system with the compensation blocks avoids fitting spacers in the upper part of the shells

- The magnetised fastening studs for the steel tubes prevent them from being cast in the BAP

- Composed of two parts: one for shimming and another for adjustment according to shell thickness