AFCAB certificate for MBT couplers

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

![[Translate to Anglais:] LEVIAT a CHR company](/fileadmin/_processed_/0/5/csm_logo-leviat-white_bf42d08d02.png)

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry.

Leviat’s engineered products and innovative construction solutions are used in a variety of market segments from residential to infrastructure, enabling users to build better, stronger, safer and faster.

3 000

employees

+60

sites worldwide

4

production on 4 continents

+30

sales in +30 countries

Blankenberge will soon have a brand-new sports complex and Leviat was allowed to contribute to

that.

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

We imagine, model and make engineered products and innovative construction solutions for a dynamic industry. We support our partners in the long term to build better, safer, stronger and faster and help turn awe-inspiring architectural visions into reality.

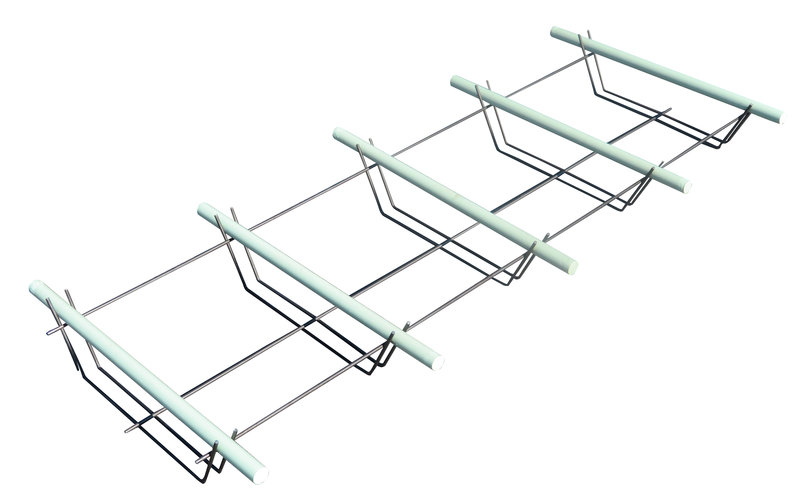

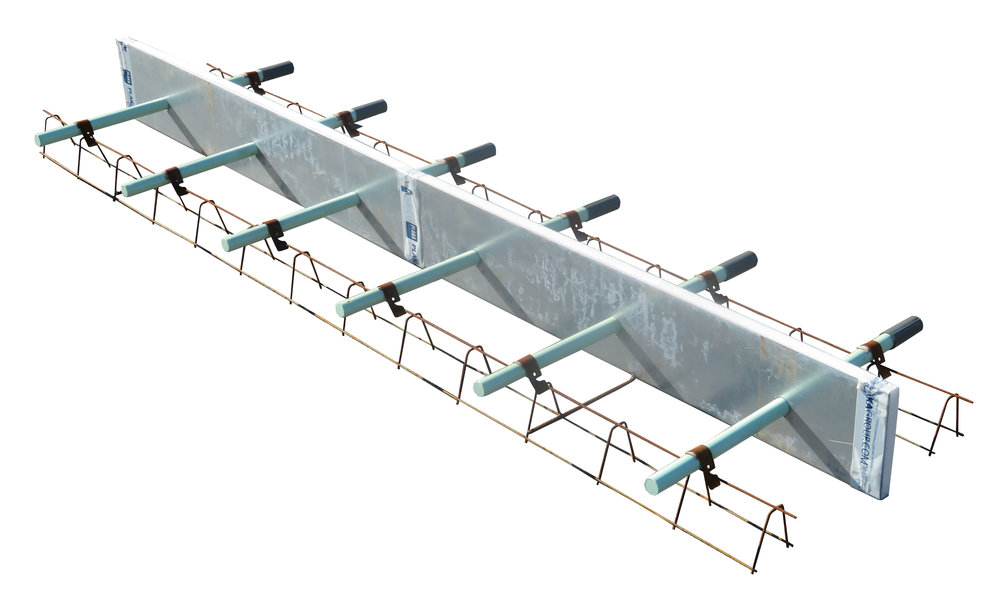

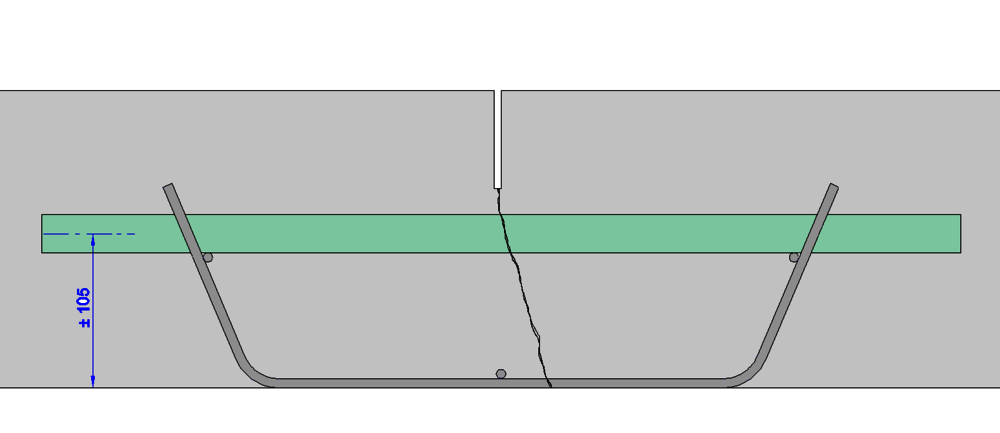

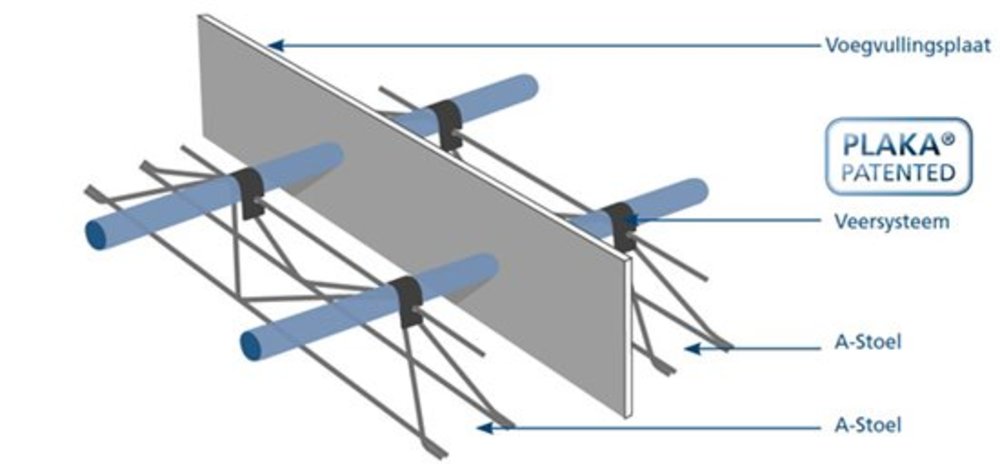

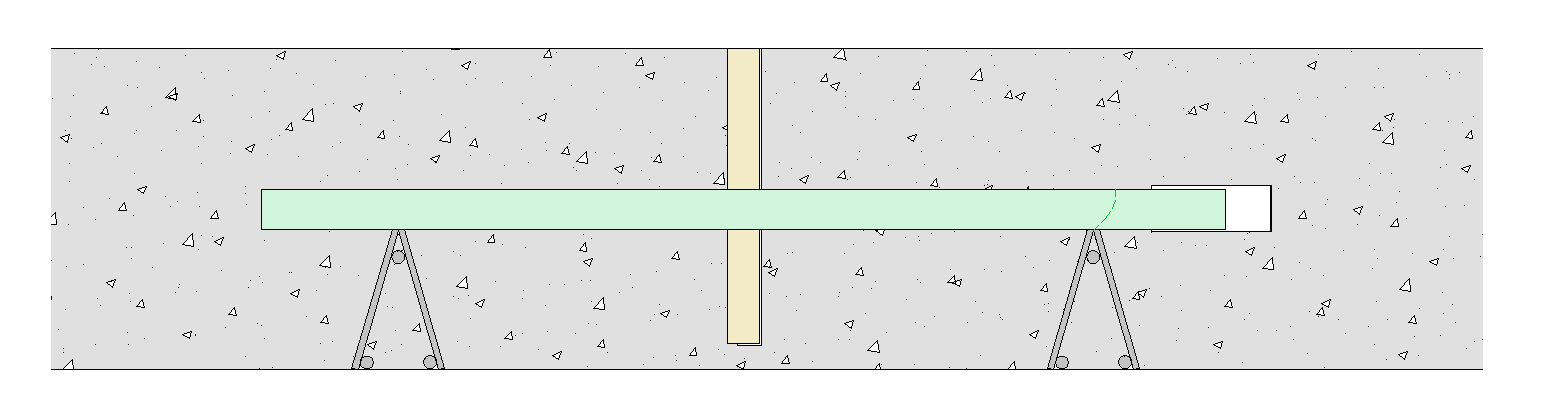

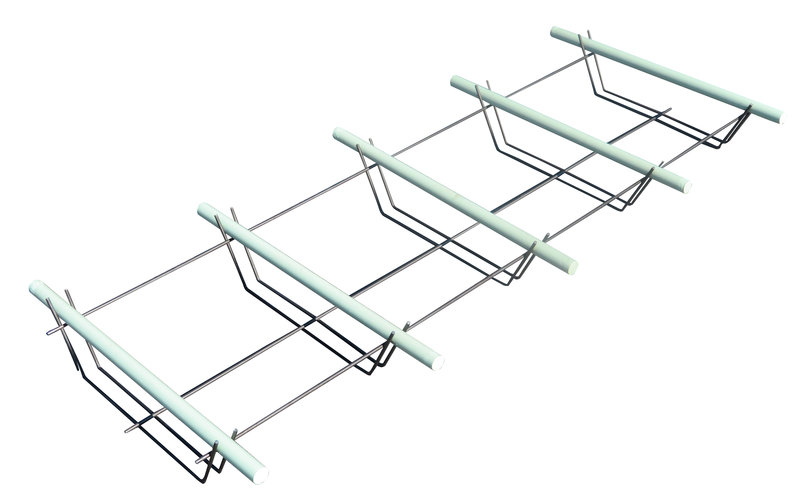

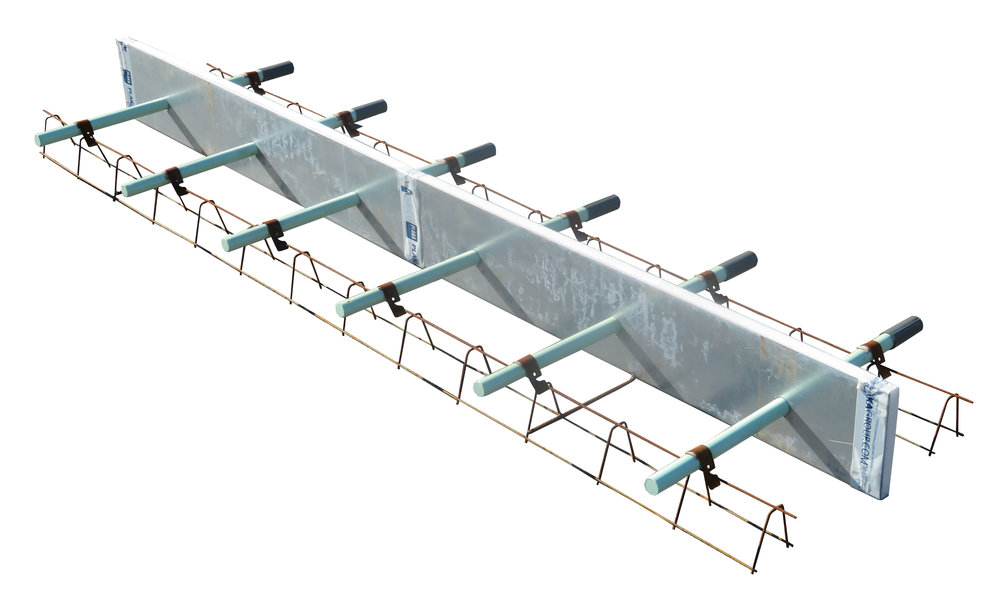

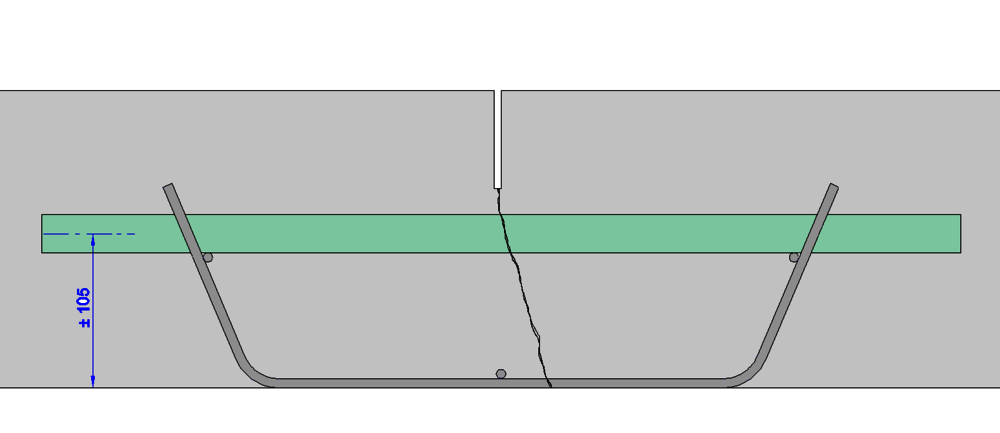

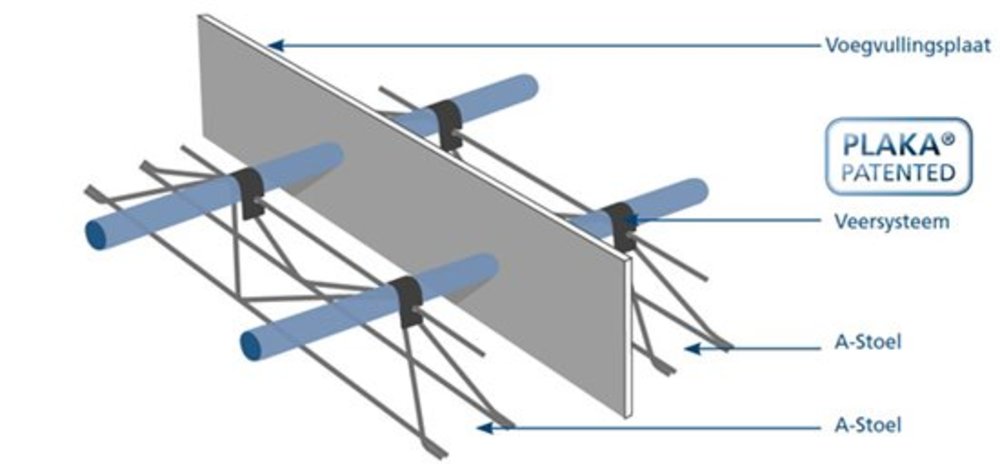

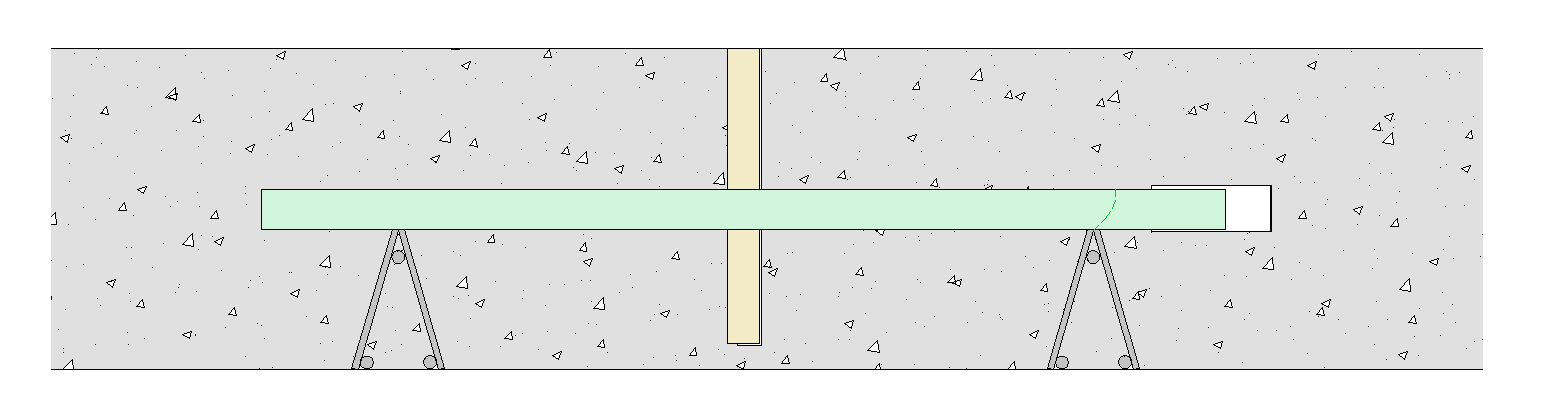

Dilatec Route is a stud holder device to be used in construction and expansion joints in slabs, and is mainly found in concrete roads, bicycle paths, unloading platforms, etc. Dilatec Route avoids risks of differential compaction of the slabs while allowing for expansion movements whenever necessary. It is mainly used where the longitudinal dimension considerably exceeds the transversal dimension. Dilatec Route is a pre-fitted element facilitating fitting on the worksite, and strongly reducing the execution time of tasks.

In the standard version, the studs are made of smooth steel, with a diameter of 25 mm and a length of 600 mm. They are protected by a thick epoxy coating resistant to salt mist, unlike the asphalt-based coatings which are typically used. Other diameters and lengths may be produced on request.

Durability tests as per Standard EN ISO 9227 (Section 3.2.2) were successfully carried out on the studs with epoxy coating. These are salt mist induced corrosion resistance tests.

Isolated studs can be used in existing concrete, for example during repair works. They are then anchored in place half-way in the concrete, and the other half is embedded in fresh second phase concrete, with or without an expansion sheath.

Road type Dilatec with joint sheath

Studs with coating are fitted on batter boards. The joint is made along the entire height of the slab, by inserting a lost formwork and sheathing to allow the free expansion of slabs on either side. This sheathing is composed of a polyethylene foam, reinforced with a slim sheet.

Technical characteristics:

/Steel compliant to the NBN EN 13877-3 standard with a resistance above 250 N/mm²

/Thick epoxy coating compliant with the ASTM A 1078/A 1078M standard

/Joint sheathing in compressible polyethylene foam, density 65 Kg/m³, for expansion joints.

Dilatec Route is a stud holder device to be used in construction and expansion joints in slabs, and is mainly found in concrete roads, bicycle paths, unloading platforms, etc. Dilatec Route avoids risks of differential compaction of the slabs while allowing for expansion movements whenever necessary. It is mainly used where the longitudinal dimension considerably exceeds the transversal dimension. Dilatec Route is a pre-fitted element facilitating fitting on the worksite, and strongly reducing the execution time of tasks.

In the standard version, the studs are made of smooth steel, with a diameter of 25 mm and a length of 600 mm. They are protected by a thick epoxy coating resistant to salt mist, unlike the asphalt-based coatings which are typically used. Other diameters and lengths may be produced on request.

Durability tests as per Standard EN ISO 9227 (Section 3.2.2) were successfully carried out on the studs with epoxy coating. These are salt mist induced corrosion resistance tests.

Isolated studs can be used in existing concrete, for example during repair works. They are then anchored in place half-way in the concrete, and the other half is embedded in fresh second phase concrete, with or without an expansion sheath.

Road type Dilatec with joint sheath

Studs with coating are fitted on batter boards. The joint is made along the entire height of the slab, by inserting a lost formwork and sheathing to allow the free expansion of slabs on either side. This sheathing is composed of a polyethylene foam, reinforced with a slim sheet.

Technical characteristics:

/Steel compliant to the NBN EN 13877-3 standard with a resistance above 250 N/mm²

/Thick epoxy coating compliant with the ASTM A 1078/A 1078M standard

/Joint sheathing in compressible polyethylene foam, density 65 Kg/m³, for expansion joints.