AFCAB certificate for MBT couplers

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

![[Translate to Anglais:] LEVIAT a CHR company](/fileadmin/_processed_/0/5/csm_logo-leviat-white_bf42d08d02.png)

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry.

Leviat’s engineered products and innovative construction solutions are used in a variety of market segments from residential to infrastructure, enabling users to build better, stronger, safer and faster.

3 000

employees

+60

sites worldwide

4

production on 4 continents

+30

sales in +30 countries

Blankenberge will soon have a brand-new sports complex and Leviat was allowed to contribute to

that.

We are particularly proud to announce that our MBT sleeve has received the AFCAB certification.

We imagine, model and make engineered products and innovative construction solutions for a dynamic industry. We support our partners in the long term to build better, safer, stronger and faster and help turn awe-inspiring architectural visions into reality.

GF type is a ferruled slipping bearing in elastomer stud with teflon slip coating.

Horizontal displacements of the structure are taken up by deforming the bearing itself. This causes a horizontal return force. The horizontal load is limited and independent from the bearing's slip coefficient.

The GF slip bearing provides free expansion with reduced horizontal reaction.

To date, no comment is available about this product

/Connection of high vertical loads

/Allow δ rotation without creating tensions outside the core

/Ensure free expansion with reduction of the horizontal load

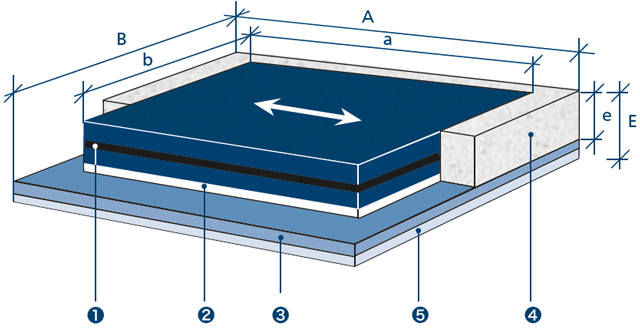

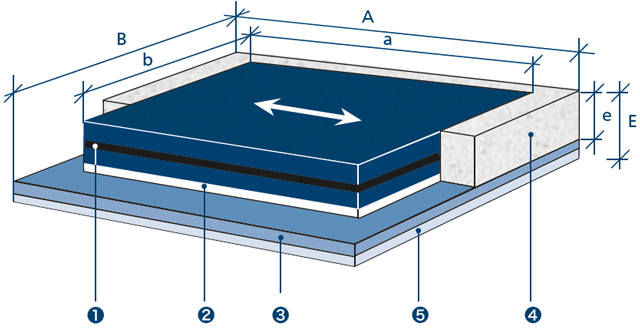

On a sintered elastomer stud (1) of 10, 14 or 20 mm, a teflon coat (2) is vulcanised.

The teflon sheet slides on an acetal sliding plate (3). The acetal plate is 2mm thick and is protected by a 2 mm elastomer sheet (5). The assembly is surrounded with a polystyrene foam (4), thus creating the expansion chamber. The current version authorizes a 20 mm slide with a sliding coefficient of μ = 0.10.

GF type is a ferruled slipping bearing in elastomer stud with teflon slip coating.

Horizontal displacements of the structure are taken up by deforming the bearing itself. This causes a horizontal return force. The horizontal load is limited and independent from the bearing's slip coefficient.

The GF slip bearing provides free expansion with reduced horizontal reaction.

To date, no comment is available about this product

/Connection of high vertical loads

/Allow δ rotation without creating tensions outside the core

/Ensure free expansion with reduction of the horizontal load

On a sintered elastomer stud (1) of 10, 14 or 20 mm, a teflon coat (2) is vulcanised.

The teflon sheet slides on an acetal sliding plate (3). The acetal plate is 2mm thick and is protected by a 2 mm elastomer sheet (5). The assembly is surrounded with a polystyrene foam (4), thus creating the expansion chamber. The current version authorizes a 20 mm slide with a sliding coefficient of μ = 0.10.