Tetraform 3070 & 3077 05.12.08

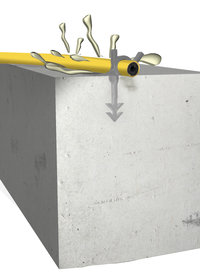

Add to my wish listWhen a traditional watertightness sheet is placed on the upper reinforcements of the slab, it is often embedded into the 1st stage concrete only by a few centimetres (coating value), which is not sufficient to offer perfect watertightness.

Thanks to the Tetraform 3070 or 3077 heel, a first stage concrete riser is created to coat the sheet by 10 cm minimum in both concreting stages.

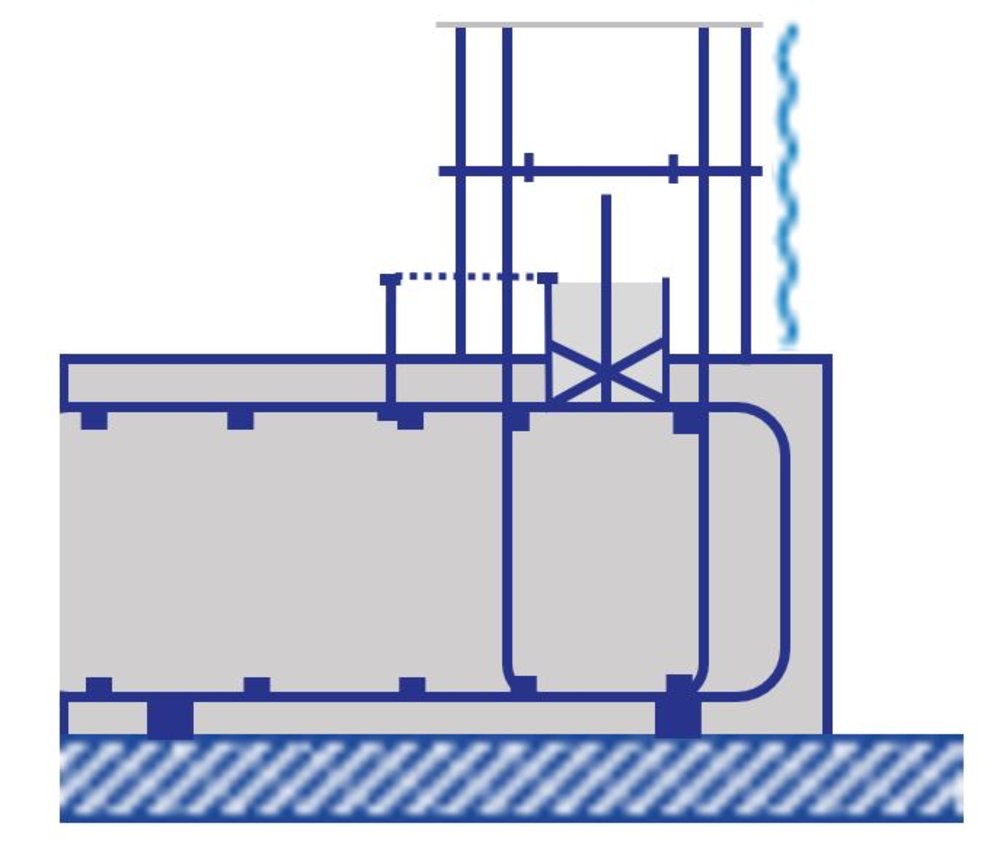

The Tetraform 3070 or 3077 heel is a high quality construction joint which is to be placed at the base of the concrete shell. The 3070 or 3077 heel is placed between the standby reinforcements of the shell and is fitted on the horizontal reinforcements of the slab.

During slab concreting, the heel created by the two vertical Tetraform 3001 strips will also be concreted.

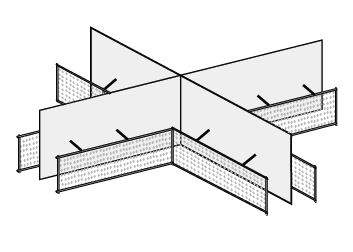

The Tetraform 3077 elements are nestable and the sheets are intended to overlap.

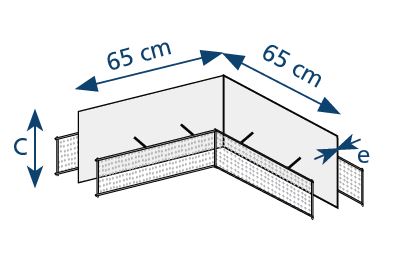

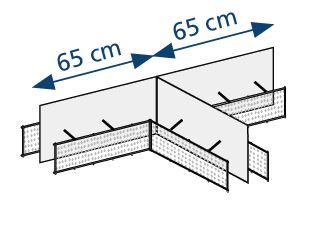

At the location of the sheet overlaps, it is strongly advised to implement proper watertightness between them to prevent any risk of capillarity effect. <br/>Two solutions are available - either the sheets are jointed, in which case the sheets must be welded or glued together; or the sheets can be separated by 5 cm minimum to ensure the concrete is able to fill the space between the 2 sheets, and therefore extend the water passage.<br/>The angles can be treated by cutting straight elements and folding them. Tetraform 3001 strips must be added to cover the outer side of the heel.

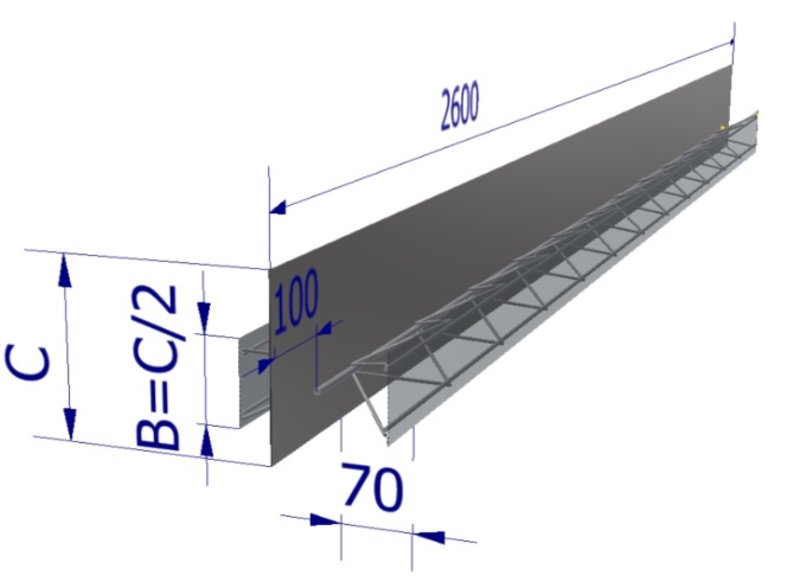

1. Tetraform 3077-1

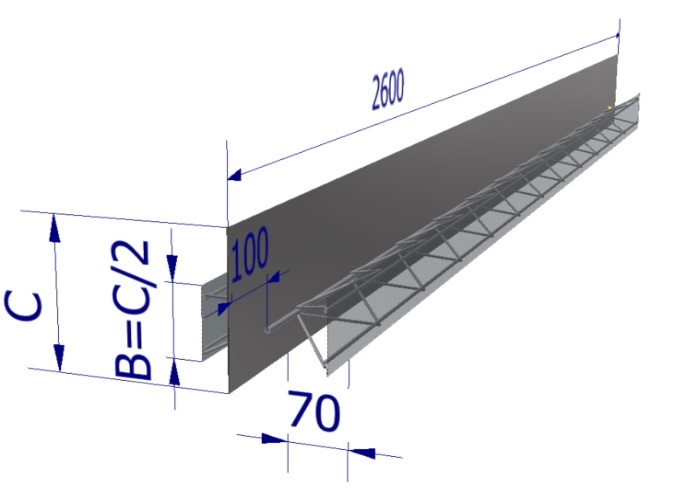

It is made of 1 strip of Tetraform 3001, welded on one side of a watertight sheet. This compact model (10 cm) was created for narrow concrete shells.

It can be supplied with a watertightness sheet in different thicknesses (1.5 or 2 mm) and different heights (200, 300 or 400 mm)

2. Tetraform 3077-2

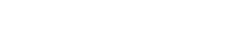

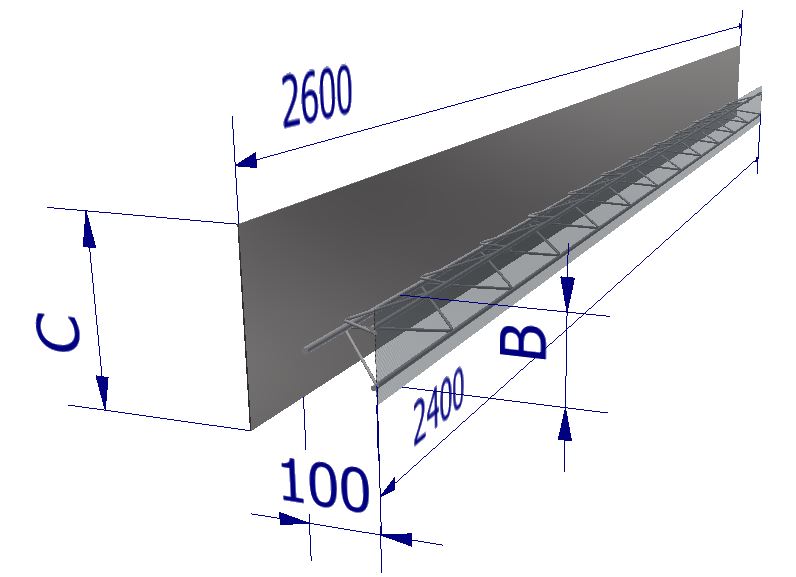

It is made of 2 strips of Tetraform 3001, welded on either side of a watertightness sheet. This 14 cm wide model is designed for shells with a thickness exceeding 24 cm.

It can be supplied with a watertightness sheet in different thicknesses (1.5 or 2 mm) and different heights (200, 300 or 400 mm)

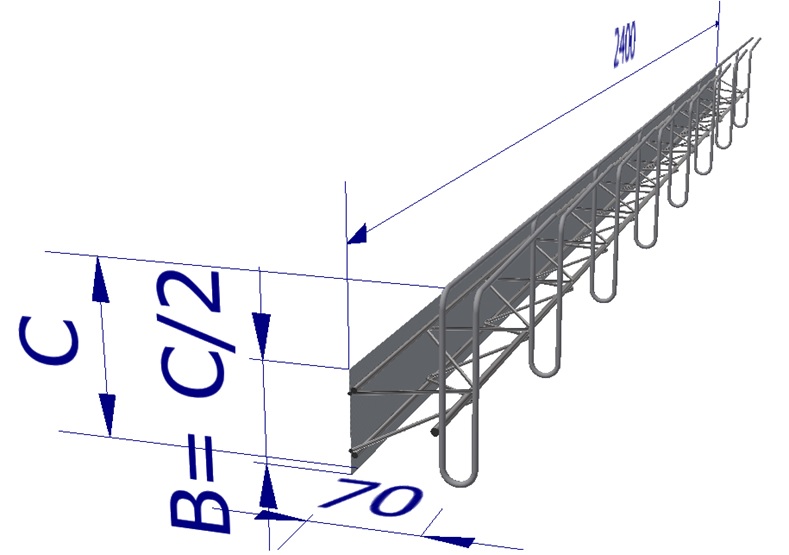

1. Tertraform 3070-1

It is made of 1 strip of Tetraform 3001, welded on one side of a metallic cradle. This cradle will allow the accommodation of a continuous PVC membrane. This compact model (10 cm) was created for narrow concrete shells.

According to the membrane chosen, the cradle will be adapted in height in order to hold the membrane properly.