an emblematic project carried out in close collaboration with our customer

Our challenge : offer a technical solution for creating thermal breaks between columns and floor slabs: the load to be transferred is relatively high, we are talking about 500 kN (50 tons) through a balcony connector. In addition, and unlike the usual application, this is a building where the supporting structure is located on the outside of the building, a so-called exoskeleton. Each column is a 700/400 mm section column, in white architectural concrete, one on two supports the interior plates.

Challenge:

Offer a technical solution for creating thermal breaks between columns and floor slabs: the load to be transferred is relatively high, we are talking about 500 kN (50 tons) through a balcony connector. In addition, and unlike the usual application, this is a building where the supporting structure is located on the outside of the building, a so-called exoskeleton. Each column is a 700/400 mm section column, in white architectural concrete, one on two supports the interior plates.

Given the location of the building, in the city center and along a road, the control office in charge of the project requires specific accidental constraints. In addition, since the breaker is part of the supporting structure of the building, particular attention to fire resistance is required.

Technical solution:

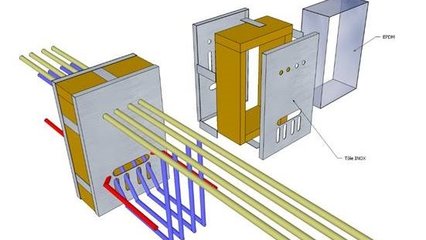

After extensive research and active cooperation between the contractor's design office and Leviat, we have developed a thermal break which can absorb considerable vertical load, horizontal loads, in accordance with thermal requirements, which are fire resistant and which also have an EPDM sealing strip for connection to other joints in the building. Completely filling the thermal break with mineral wool is essential to achieve the required fire resistance. We thus made a case with a mineral wool panel and leave an empty space in the middle so that the stainless steel rebar can be easily let through. Once the thermal break is fully assembled, the central part is insufflated with mineral wool by a specialized company.

Therefore, we developed in close cooperation with our customer a tailor-made solution with our Isotec elements adapted to this emblematic project.

Read also