Tetraform 3004-3005 05.12.02

Add to my wish listThe construction of a concreting stop formwork in reinforced concrete structures has specific requirements and is often time-consuming. Protruding reinforcements, sheets or watertightness strips hinder access for the quick construction of a formwork. This causes

a considerable increase of the time dedicated to the performance of this highly strategic job.

The Tetraform system offers an effective and operational solution to this problem, in compliance with the currently enforced standards.

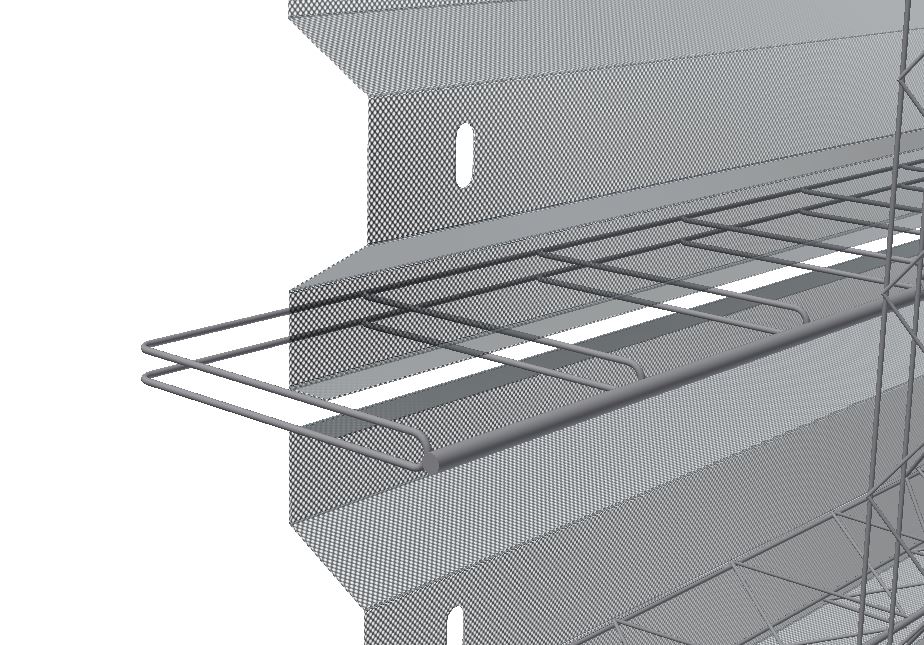

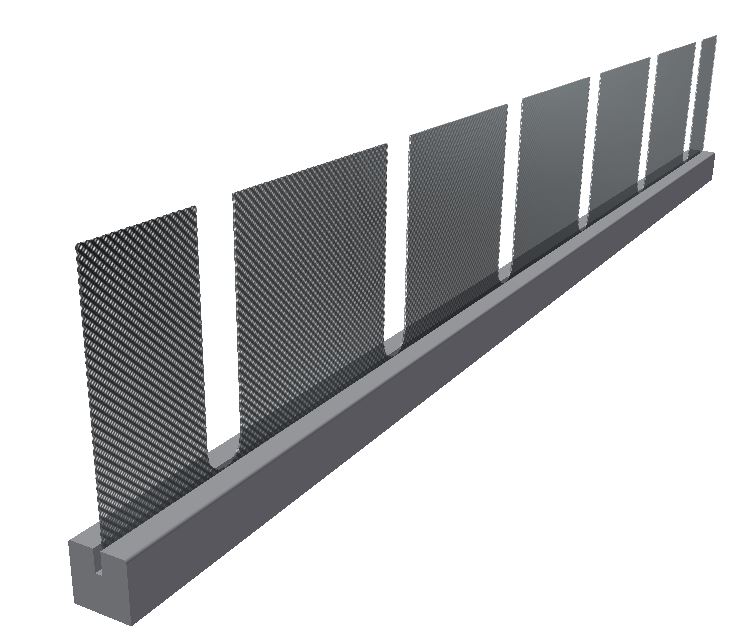

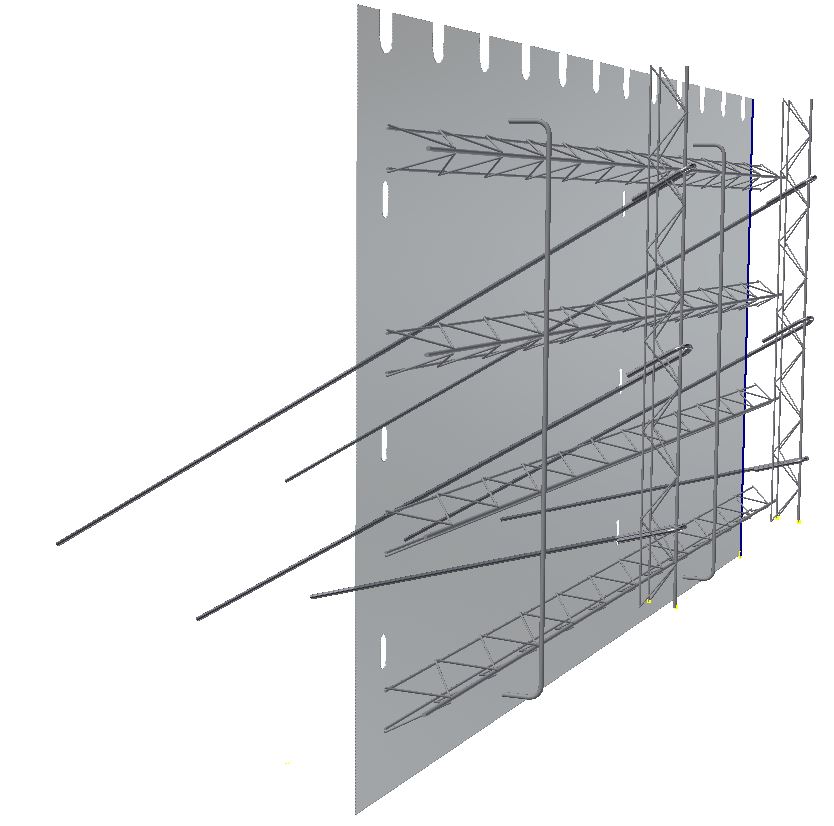

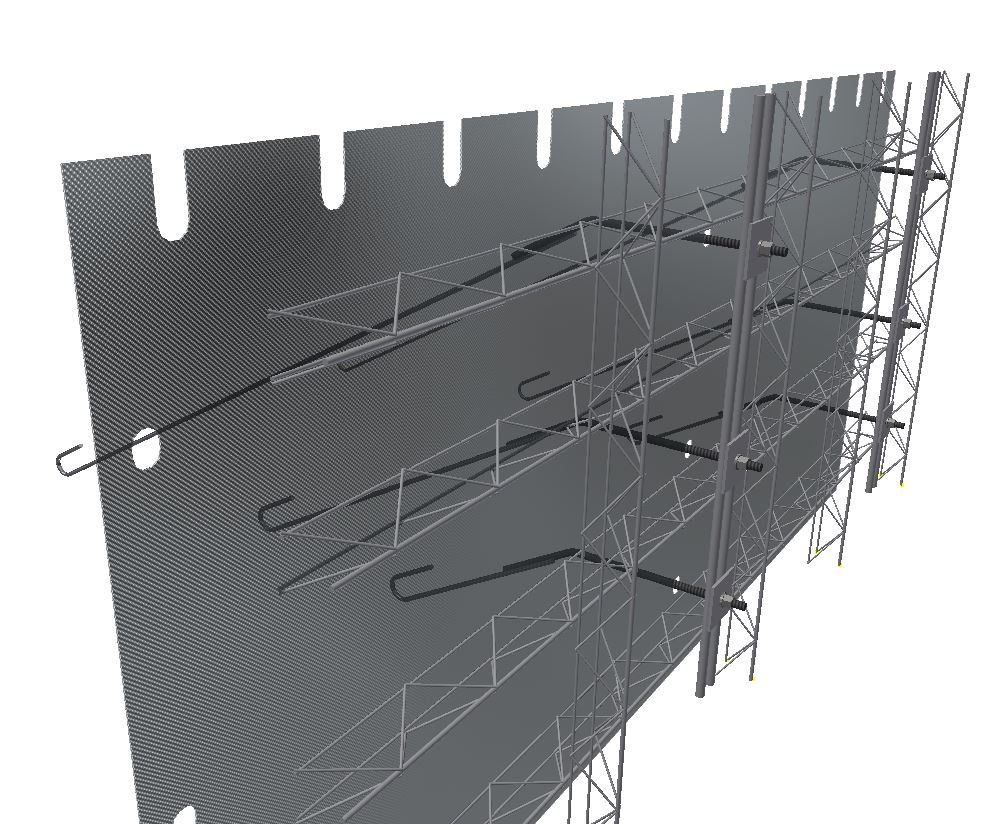

The 3004 and 3005 systems are autostable, ready for use and require no stiffeners on-site, which allows daily concreting to be carried out, when permitted by the situation.

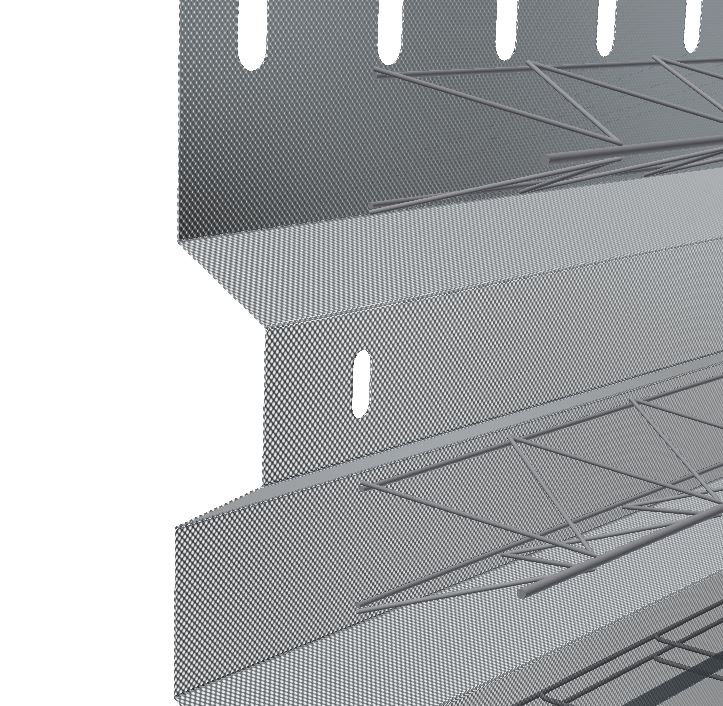

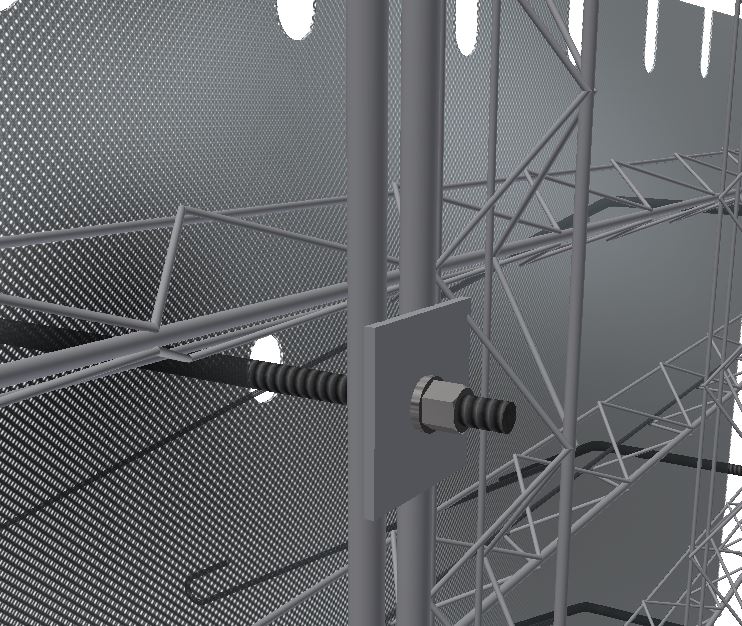

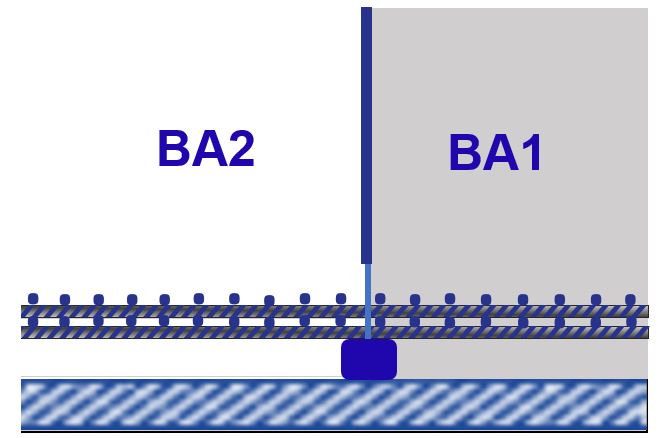

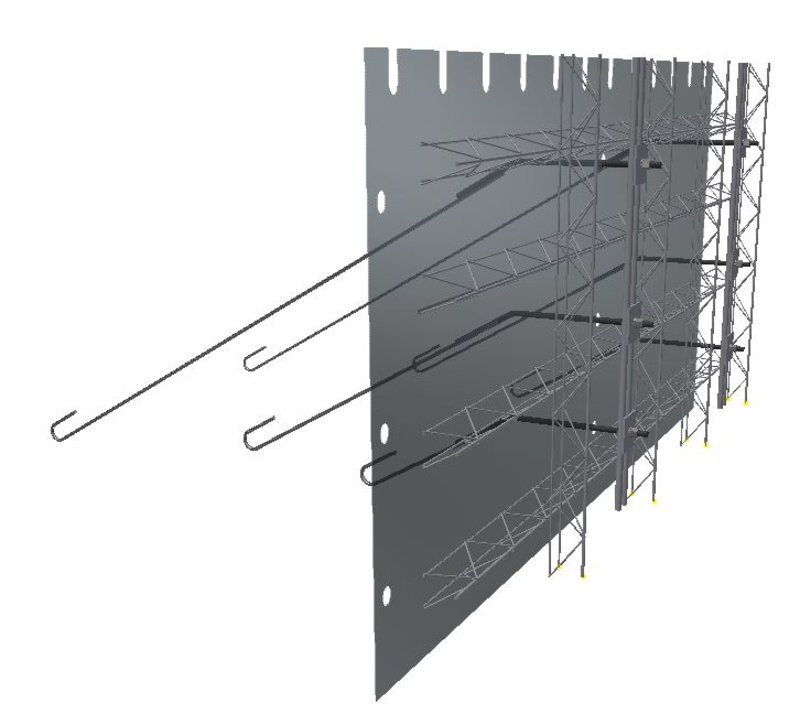

They are integral to the reinforcement of raft foundations by using Tetrafix tie rods. Their distribution allows resistance to the concrete load without deformation.

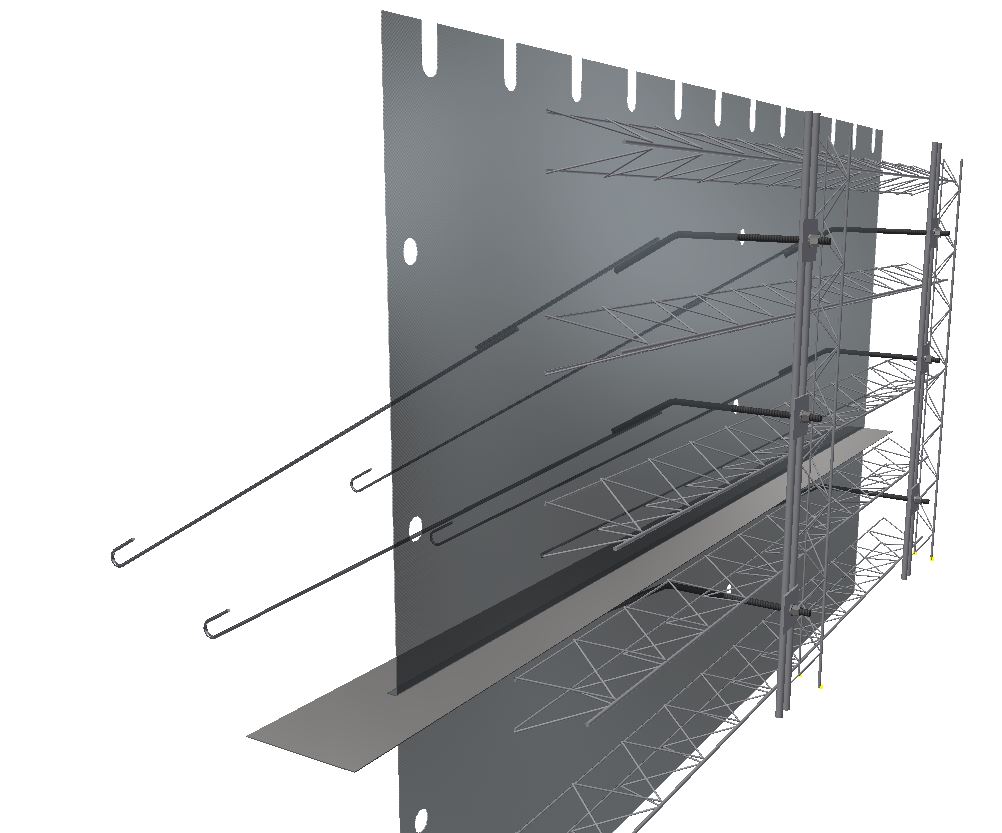

Combs can be shaped optionally to position the reinforcements.

- Improves resistance of adherence of the construction joint

- Considerable gain in fitting time versus a traditional method

- No stripping phase

- Tetraform is perfectly stable in dimensions

- Its two sides withstand concrete pressure

- Fitting is performed between the reinforcement beds

- Tetraform is not an obstacle for continuous reinforcements

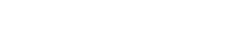

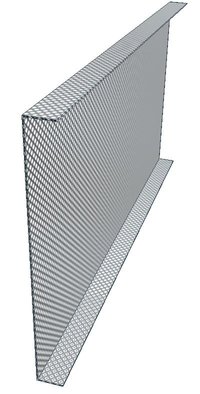

The Tetraform is made of cold drawn and degreased expanded metal with properties studied to ensure the construction joint has a roughness such that the concrete maintains it homogeneity, even when using self-compacting concrete. Reinforcements are positioned to withstand pressure loads.

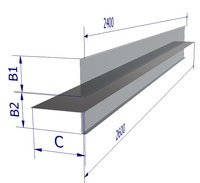

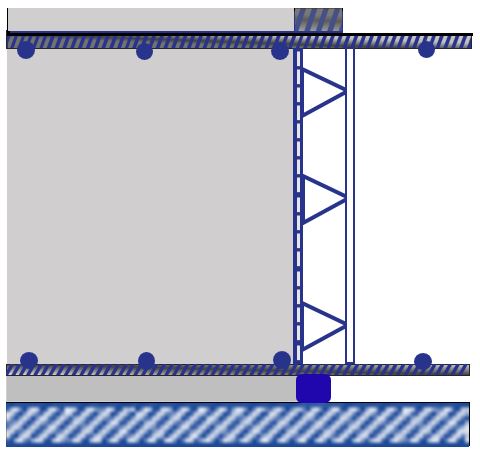

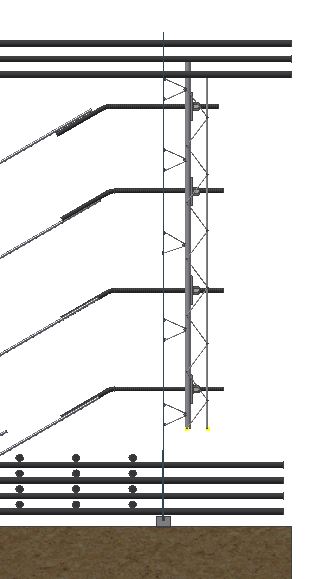

Concreting stop, treating concrete elements from 50 cm wall thickness and 80 cm height on a raft foundation. Horizontal stiffeners in triangular girders are distributed over the width of the formwork. When HA12 TetraFix anchoring bars are used, vertical stiffeners are added. Models 3004 can be fitted with sheets or cradles to ensure a watertightness function.

- Models dimensioned to withstand concrete pressure

- The stiffeners are offset by 10 cm to allow expanded metal continuity in juxtaposition

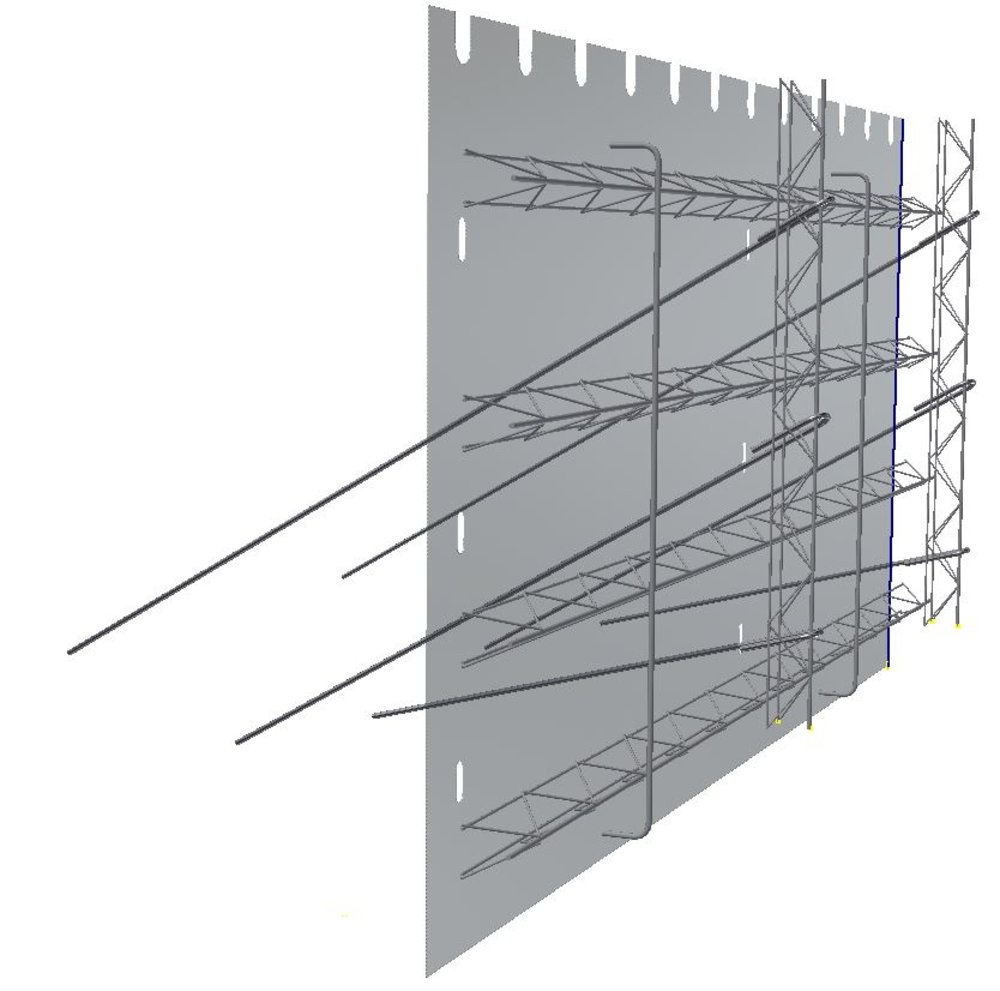

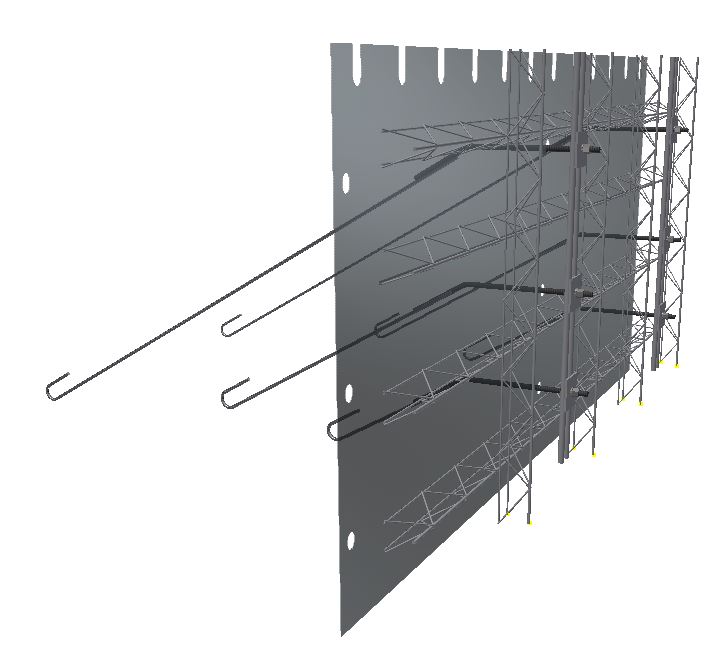

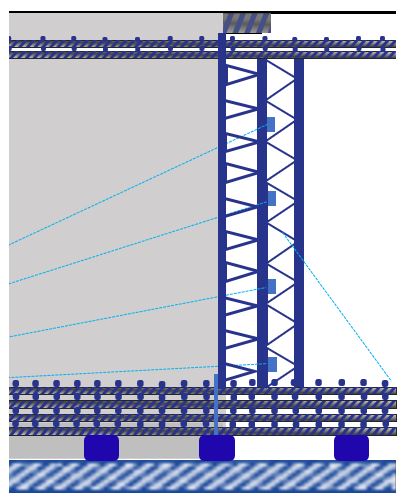

Ultra-strong concrete casting stop for thicknesses beyond 120 cm on walls and 150 cm on raft foundations. A 20 cm overlapping zone allows assembly of the panels. TetraFix anchoring bars in HA12 are included systematically.

- Reinforced model made integral with the raft foundation reinforcements, thanks to a distribution of TetraFix anchoring bars