Alu door frame 04.22.05

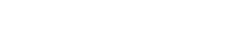

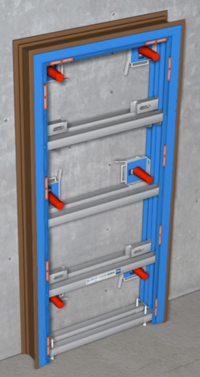

Add to my wish listThe Aluminium frame allows implementing metal doors to form: composed of 2 magnetised elements of 15 kilos, adjustable in thickness for shells from 15 to 20 cm, it allows perfect positioning and holding of the door. It is compatible with all doors in the market.

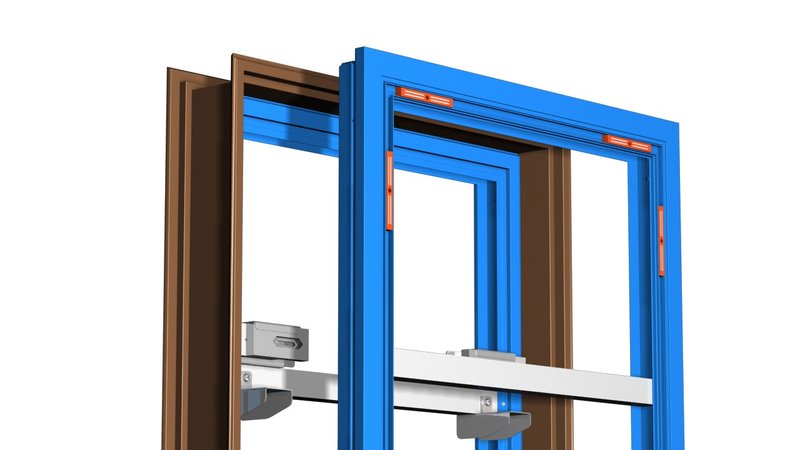

Feet jacks allow the mannequin to be adjusted in height. <br/>Optional part for 25 cm shell. <br/>Mannequin rigidity is ensured by stiffeners. <br/>Accessories recommended: 6 mannequin magnets, type R600 or R610, with compensation cones to guarantee proper fitting of the frame.

1. Positioning of the first part

- Apply the stripping fluid on all faces.

- Mark a level reference line on the form panel.

- Define the door opening direction: right push or left push.

- Choose and position the first part of the mannequin.

- For the height adjustment, the top of the upper stiffener is located at 1 m from the top.

- Adjust the plumb line either with a level on the cross-piece, or with the PLAKAFil plumb line on the sides.

For increased safety, place two R600 magnets under the upper cross-piece.

Do not adjust the jacks at this step, to allow the passage of the frame spacer profile.

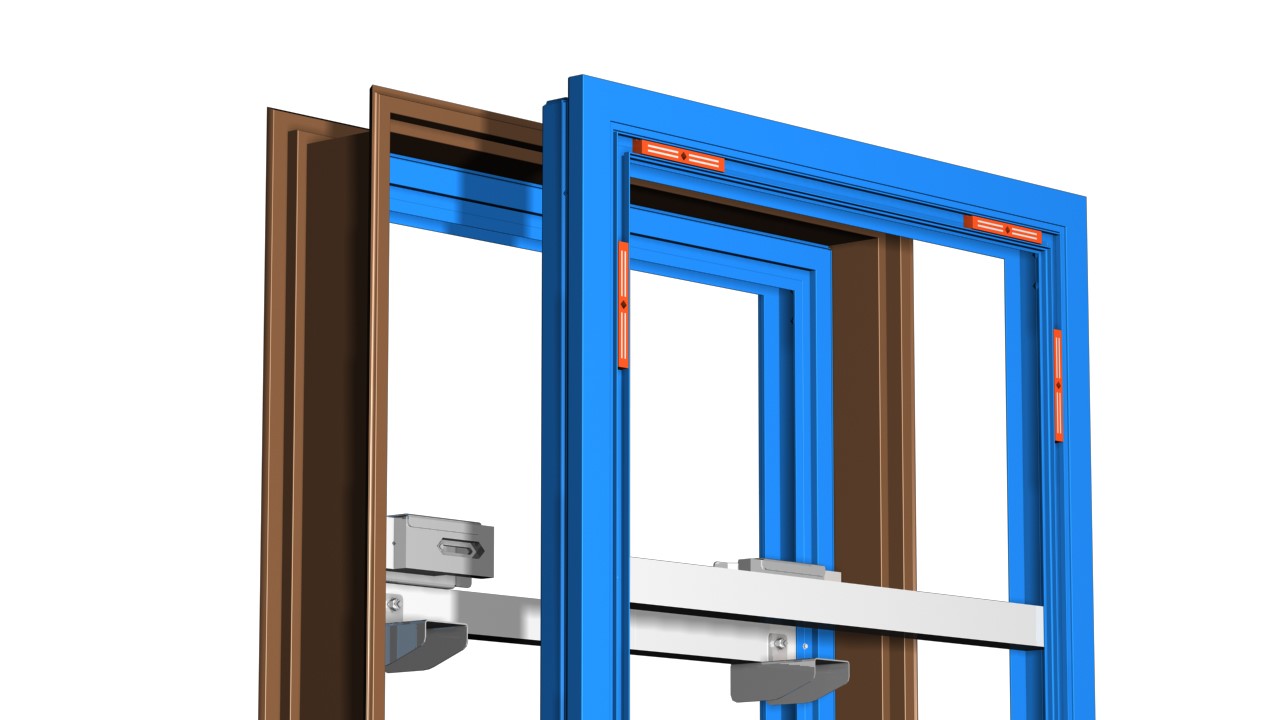

2. Fitting the metallic frame

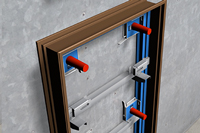

- Fit the frame in place and adjust the jacks of the first part.

- Adjust the plumb line either with a level on the cross-piece, or with the PLAKAFil plumb line on the sides.

- Adjust the shims for the shell thickness: from 16 to 20 cm

3. Positioning of the second part

- Fit the second part of the frame mannequin.

- Add the 4 R600 magnets necessary for holding the mannequin at the time of concrete casting (you must have a total 6 R600 magnets with compensation cones).

- Adjust the two jacks by moving them so that they are just above the ground.

- Close the form panel.