Plakasol 04.09.01

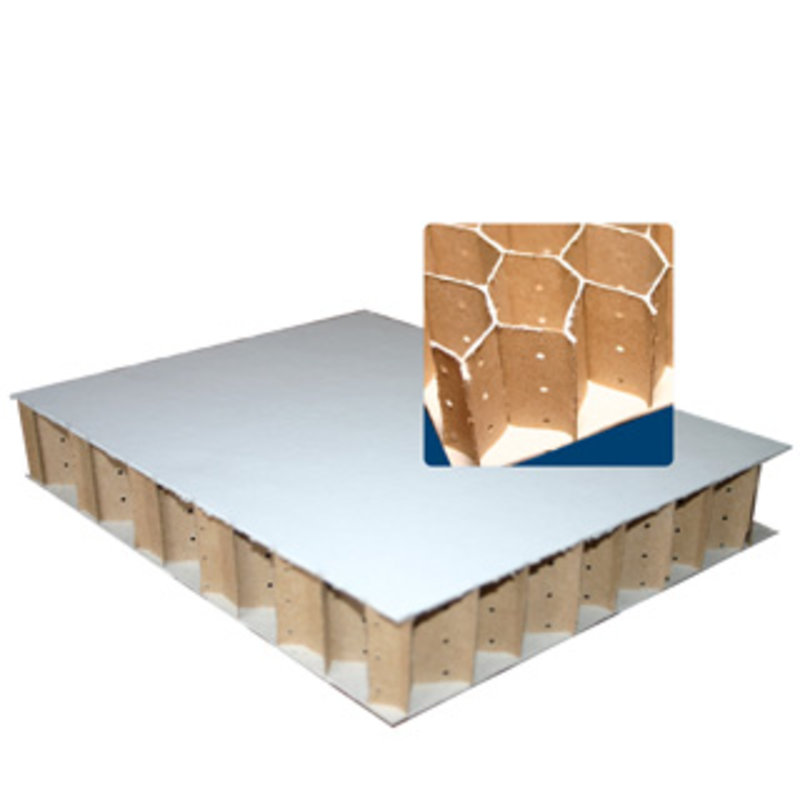

Add to my wish listThe construction of a building on ground with clay characteristics, likely to cause the shrinkage and swelling phenomenon, requires the creation of a space free of any constraint under the floor slabs. This space must have a height at least equal to that of the potential swelling of clay, which is determined by the Soil Survey Office using oedometric swelling tests. The PLAKASOL process allows this space to be created using hydro-degradable cell cardboard panels used as lost formwork for obtaining a self-supporting slab.

- PLAKASOL cell cardboard panels of 2.35 x 1.20 m

- Available in 40, 50, 60, 90 and 100 mm thickness

- Can also be cross-laminated for higher thickness without altering their resistance to compaction

- Resistance to compression when the boards are fully:

- Dry: 5 bar (10 t/m²)

- Humid: negligible

The cell structure (honeycomb) is made of 25 mm recycled cardboard, cross-laminated between two cardboard sheets using hydrosoluble glue in order to remove any resistance after humidification.

This product was qualified by tests performed in the presence of SOCOTEC

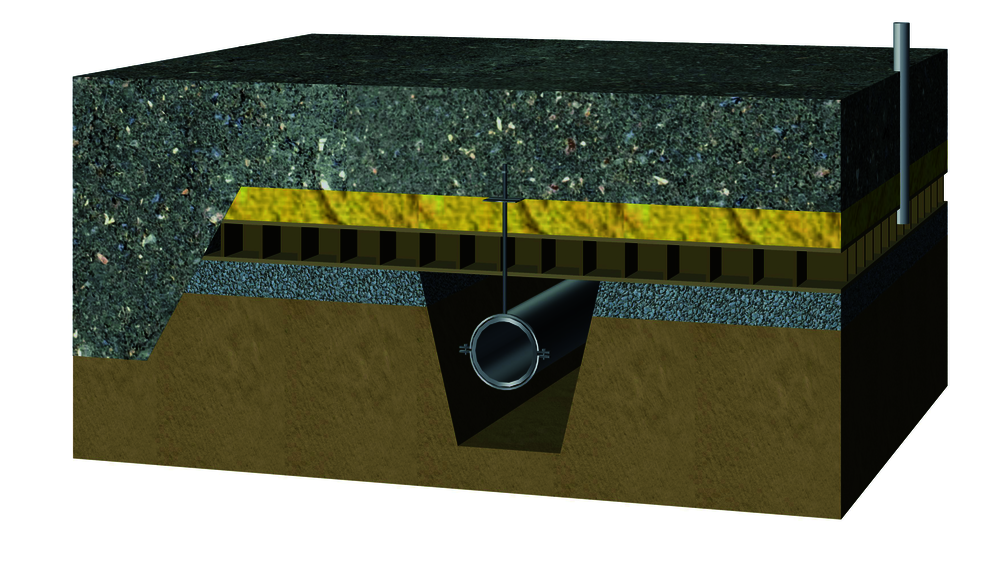

The ground must be flat and dry, which is obtained with a gravel of sufficient thickness (at least 5cm) to avoid water infiltration.

1. Spread the 50 μ polyethylene film on the ground. Fit the PLAKASOL panels edge to edge, without any spaces between the panels. Raise the film onto the panels and tape them, then cover everything in order to seal the formwork. Fit the reinforcement calculated by the Engineering Office. It must be noted that the use of concrete reinforced with fibres is perfectly adapted to the PLAKASOL process

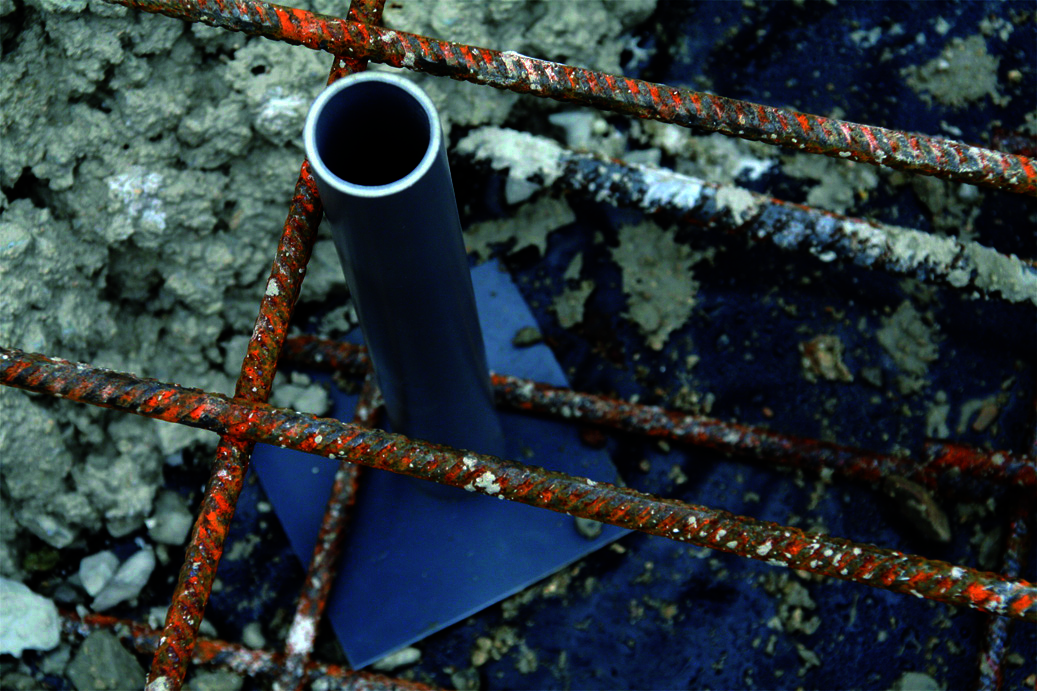

2. Place the PVC tubes or water injection cuts (1 for 25 m2) by perforating the box. Check the tube height adjustment with respect to the height of the casting

3. Fit the reinforcement calculated by the Engineering Office. Promptly cast the concrete of the supported slab, which must in no event be self-levelling.

4. When the slab has become self-supporting, inject the water into the formwork of the box using the chutes or porous pipe, according to the destination of the slab. The concrete can also be drilled if the chutes have not been used. 3 to 6 litres of water per m² is sufficient, according to the cardboard thickness used. Without a flow meter on the worksite, water is left to run at full flow for 2 to 4 minutes through a pipette to obtain these volumes.

The water introduced in the formwork eliminates its resistance and therefore allows the ground to expand freely under the supported slab.

Monitor the quantity of water introduced to prevent any alteration of the ground on the level of the foundations. The injection chutes will then be filled.

If openings are included in the crawl spaces, they must be protected from pests by grids after cutting the opposite polyethylene film, ensuring ventilation of the space obtained under the supported slab.